Understanding the Core: The Meaning and Profound Significance of Business Inventory

In the intricate world of commerce and industry, few concepts are as fundamental, yet as often underestimated, as "inventory." For many, it simply conjures images of goods stacked in a warehouse. However, for a business, inventory is far more than just a collection of items; it is a critical asset, a strategic lever, a significant cost, and a vital determinant of operational efficiency, customer satisfaction, and ultimately, profitability. Understanding the true meaning of business inventory is paramount for anyone involved in managing, owning, or analyzing a commercial enterprise.

This article will delve into the multifaceted meaning of business inventory, exploring its various forms, its immense significance, the inherent challenges it presents, and its critical impact on a company’s financial health and strategic direction.

What Exactly is Business Inventory? A Definitional Deep Dive

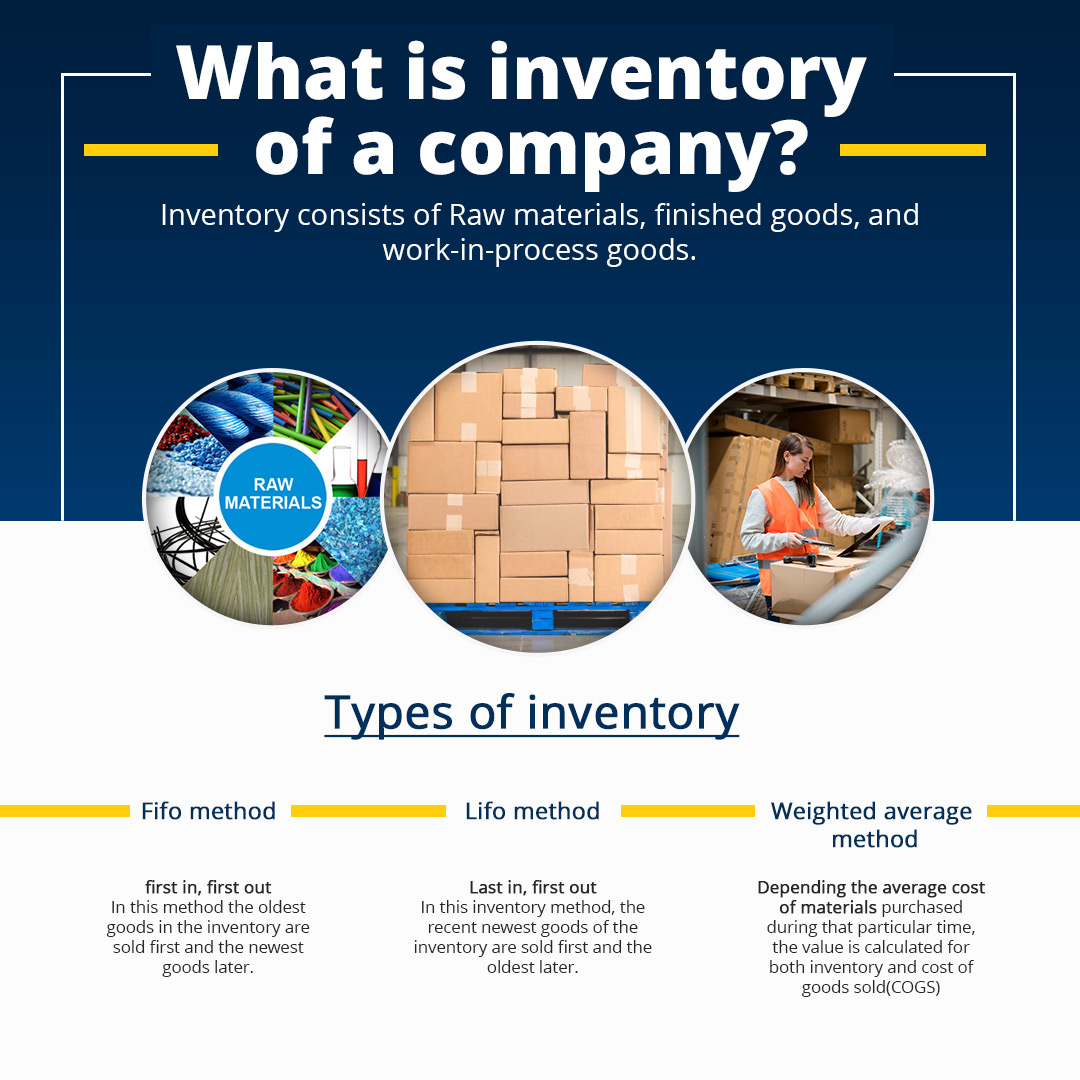

At its most basic, business inventory refers to the goods and materials that a business holds for the ultimate purpose of resale or use in the production of goods for resale. It encompasses all items a company has in its possession that contribute to its revenue generation cycle. These items are considered current assets on a company’s balance sheet, meaning they are expected to be converted into cash or used up within one year.

To truly grasp its meaning, inventory can be broken down into several distinct categories, each playing a unique role in the business process:

-

Raw Materials: These are the basic inputs or components that a company purchases from suppliers to be transformed into finished products. For example, for a bakery, flour, sugar, and eggs are raw materials. For an automobile manufacturer, steel, rubber, and electronic components are raw materials. Holding adequate raw materials ensures continuous production without delays.

-

Work-in-Process (WIP) / Goods-in-Process (GIP): This category includes items that have begun the manufacturing process but are not yet completed finished goods. They have undergone some transformation but require further processing, assembly, or finishing before they can be sold. Partially assembled furniture, half-baked bread, or a car chassis on the assembly line are examples of WIP. Managing WIP efficiently is crucial for optimizing production flow and minimizing bottlenecks.

-

Finished Goods: These are products that have completed the entire manufacturing process and are ready for sale to customers. They are fully assembled, tested, packaged, and awaiting shipment. A fully baked cake, a finished smartphone, or a packaged garment are examples of finished goods inventory. This is the most visible form of inventory and directly impacts sales revenue.

-

Maintenance, Repair, and Operations (MRO) Supplies: While not directly incorporated into the final product, MRO supplies are essential for the ongoing functioning of the business. This includes items like spare parts for machinery, office supplies, cleaning materials, lubricants, and safety equipment. Without these, production lines could halt, or daily operations could be disrupted. Though not for resale, their availability is critical for operational continuity.

Understanding these categories is the first step in comprehending the holistic meaning of inventory. It’s not just "stuff"; it’s a dynamic collection of assets at different stages of value creation.

The Profound Significance of Inventory: Why It Matters So Much

The meaning of business inventory extends far beyond its definition. Its significance permeates every aspect of a business, influencing financial stability, operational efficiency, customer relationships, and strategic positioning.

-

Financial Impact: Inventory is a major current asset on the balance sheet, often representing a substantial portion of a company’s invested capital. Its valuation directly affects a company’s asset base, solvency, and liquidity ratios. On the income statement, the cost of inventory sold (Cost of Goods Sold – COGS) directly impacts gross profit and, subsequently, net income. Furthermore, managing inventory impacts cash flow; tying up too much capital in inventory reduces available cash for other investments or operations.

-

Operational Efficiency and Production Continuity: Sufficient inventory levels, especially for raw materials and WIP, ensure that production lines can run smoothly and continuously without interruptions. Stockouts of critical components can halt production, leading to costly downtime, missed deadlines, and lost sales. Inventory acts as a buffer against uncertainties in supply and demand.

-

Customer Satisfaction and Sales Opportunities: For finished goods, inventory directly relates to a company’s ability to meet customer demand promptly. Having the right products available at the right time is crucial for customer satisfaction. Stockouts lead to lost sales, frustrated customers, and potential shifts to competitors. Conversely, having readily available products can enhance customer loyalty and drive repeat business.

-

Strategic Advantage: Effective inventory management can be a source of competitive advantage. Companies that can quickly respond to market changes, offer a wider variety of products, or guarantee faster delivery often do so through strategic inventory positioning. It allows businesses to capitalize on market trends, promotions, or seasonal demands.

-

Risk Mitigation: Inventory can serve as a buffer against various risks. Safety stock, for instance, protects against unexpected spikes in demand or unforeseen supply chain disruptions (e.g., natural disasters, supplier issues). Anticipation stock can hedge against predicted price increases or potential labor strikes.

The Double-Edged Sword: Challenges and Costs Associated with Inventory

While essential, inventory is not without its drawbacks. Its meaning also encompasses a significant array of challenges and costs that, if not managed properly, can erode profitability and cripple a business.

-

Holding or Carrying Costs: These are the expenses incurred for storing and maintaining inventory. They include:

- Storage Costs: Rent or depreciation of warehouse space, utilities, shelving, and equipment.

- Insurance: Premiums to cover loss, damage, or theft of goods.

- Obsolescence: The risk that inventory becomes outdated, damaged, or expired before it can be sold (especially critical for high-tech, fashion, or perishable goods).

- Spoilage/Damage: Goods that deteriorate or get damaged while in storage.

- Shrinkage: Loss due to theft, administrative errors, or misplacement.

- Opportunity Cost: The capital tied up in inventory could otherwise be invested in other productive assets or initiatives, earning a return.

-

Ordering Costs: Expenses associated with placing and receiving orders from suppliers, including administrative costs, transportation, and inspection.

-

Setup Costs: For manufacturing, these are the costs incurred to prepare a machine or process for manufacturing an order (e.g., retooling, cleaning).

-

Stockout Costs: The negative consequences of not having inventory when needed. This includes lost sales, expedited shipping fees, production delays, damage to brand reputation, and potential loss of customer loyalty.

Balancing these costs is the essence of effective inventory management. Too much inventory incurs high holding costs and obsolescence risk; too little leads to stockouts and lost sales.

Types of Inventory Beyond the Basic Categories

Beyond the raw materials, WIP, and finished goods classification, inventory can also be understood by the purpose it serves:

-

Cycle Stock: This is the inventory needed to meet average demand during the normal course of business operations. It’s the inventory that’s depleted and replenished regularly.

-

Safety Stock (Buffer Stock): Extra inventory held to guard against unexpected fluctuations in demand or supply. It’s a cushion to prevent stockouts.

-

Anticipation Stock (Seasonal Stock): Inventory accumulated in advance of a peak selling season, a planned promotion, or an expected price increase. For example, toy manufacturers build up anticipation stock before the holiday season.

-

In-Transit Stock (Pipeline Inventory): Goods that have left the supplier’s warehouse but have not yet arrived at the buyer’s location. This inventory is "on the way."

-

Speculative Stock: Inventory bought in larger quantities than immediately needed, anticipating future price increases or supply shortages.

-

Decoupling Inventory: Inventory held between successive stages of a production process to ensure that if one stage breaks down or slows, the subsequent stages are not immediately affected.

The Role of Inventory Management

Given the critical meaning and associated costs of inventory, robust inventory management is indispensable. This involves the systematic tracking, storing, and ordering of inventory. Its goal is to achieve the optimal balance between having enough inventory to meet demand and minimizing holding costs and potential losses.

Key aspects of inventory management include:

- Forecasting Demand: Accurately predicting future customer needs.

- Inventory Control Systems: Implementing methods like Just-in-Time (JIT), Economic Order Quantity (EOQ), ABC analysis, and Material Requirements Planning (MRP) to optimize inventory levels.

- Supplier Relationship Management: Ensuring reliable and timely delivery of raw materials.

- Warehouse Management: Efficient organization, storage, and retrieval of goods.

- Technology Integration: Utilizing ERP (Enterprise Resource Planning) and WMS (Warehouse Management Systems) software for real-time tracking and decision-making.

Conclusion: Inventory as a Strategic Imperative

The meaning of business inventory is multifaceted and profound. It is not merely a collection of items, but a dynamic asset that embodies a company’s operational capability, financial health, and customer commitment. From raw materials awaiting transformation to finished goods ready for market, each category of inventory plays a vital role in the value chain.

While essential for continuity and customer satisfaction, inventory also carries significant costs and risks. Therefore, a deep understanding of its meaning, coupled with sophisticated management strategies, is not just good practice—it is a strategic imperative. Businesses that master the art and science of inventory management are better positioned to optimize their financial performance, enhance operational efficiency, delight their customers, and secure a sustainable competitive advantage in an ever-evolving marketplace. Inventory, in essence, is the lifeblood of commerce, and understanding its true meaning is the first step toward business excellence.