The Master Key to Business Success: Understanding and Utilizing a Business Inventory List Sample

In the intricate dance of commerce, inventory is often the unsung hero, the silent backbone supporting every transaction, every customer promise, and ultimately, every business’s financial health. From a small boutique selling handmade crafts to a sprawling e-commerce giant processing thousands of orders daily, the efficient management of goods is paramount. At the heart of this efficiency lies a well-structured Business Inventory List.

This article will delve deep into the critical importance of an inventory list, explore its essential components through a detailed sample, discuss different types of inventory, outline methods for effective creation and maintenance, and highlight best practices to transform this simple document into a powerful strategic tool for sustainable business growth.

The Indispensable Role of an Inventory List

Imagine trying to navigate a complex city without a map, or bake a cake without knowing the ingredients you have on hand. That’s precisely what running a business without a robust inventory list feels like. Its importance transcends mere record-keeping; it’s a strategic imperative with far-reaching impacts:

-

Financial Accuracy and Valuation: Inventory is a significant asset on a company’s balance sheet. An accurate list ensures correct asset valuation, impacts the Cost of Goods Sold (COGS), and is crucial for tax purposes and financial reporting. Mismanagement can lead to inaccurate profit calculations and misguided financial decisions.

-

Operational Efficiency: Knowing precisely what you have, where it is, and how much is available prevents stockouts (losing sales due to unavailability) and overstocking (tying up capital in slow-moving or obsolete items). It streamlines order fulfillment, production schedules, and overall workflow.

-

Informed Decision-Making: An up-to-date inventory list provides the data needed for strategic purchasing, pricing, and sales decisions. It helps identify popular items, slow movers, and potential bottlenecks, guiding marketing efforts and product development.

-

Loss Prevention: By tracking every item, businesses can minimize losses due to theft (shrinkage), damage, or obsolescence. It creates accountability and helps identify discrepancies quickly.

-

Enhanced Customer Satisfaction: Prompt and accurate order fulfillment is directly linked to customer satisfaction. An efficient inventory system ensures that products are available when customers want them, leading to repeat business and positive reviews.

-

Supply Chain Optimization: A clear inventory picture enables better communication with suppliers, leading to more favorable terms, reduced lead times, and a more resilient supply chain.

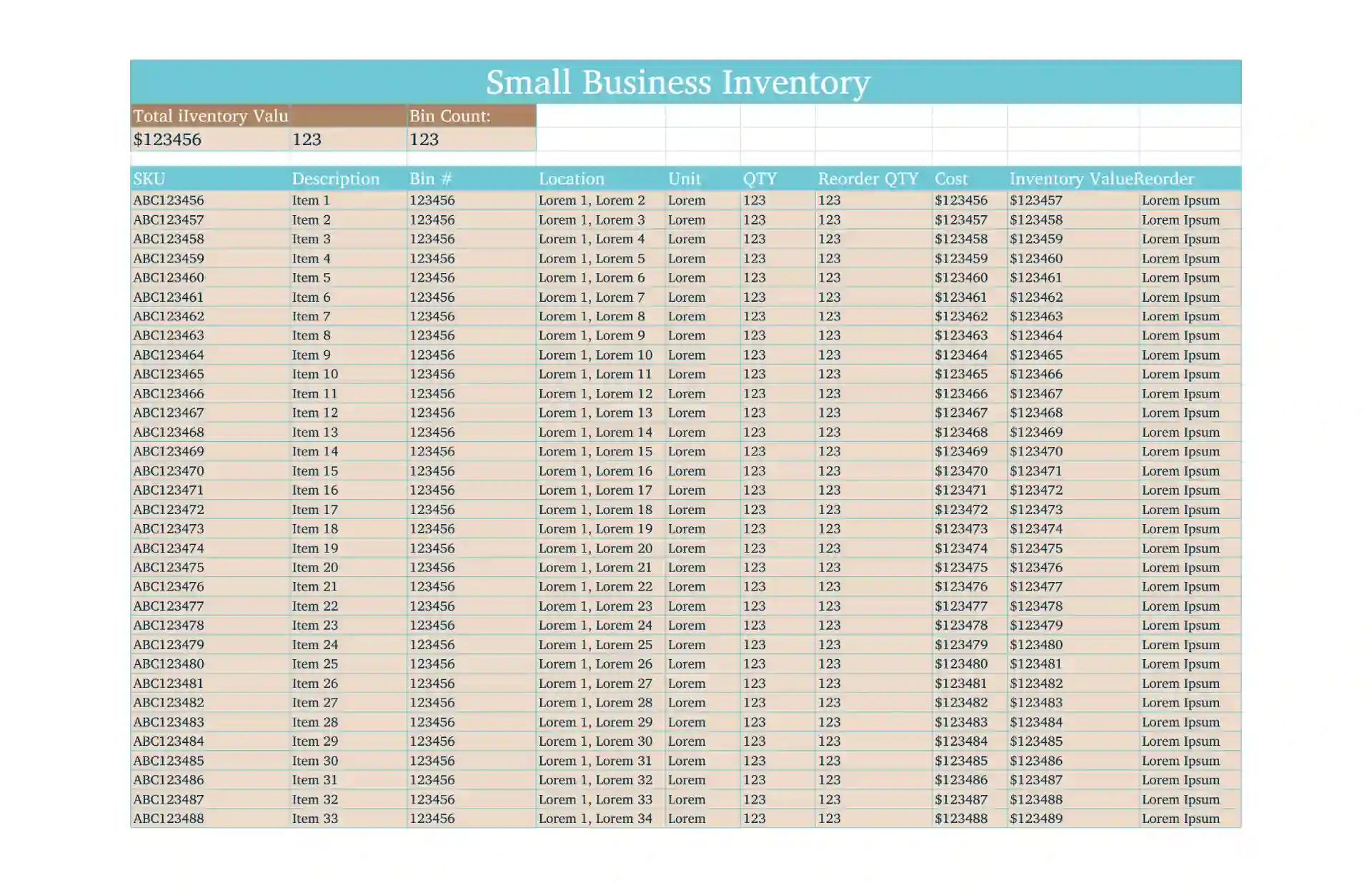

Key Components of an Effective Business Inventory List Sample

While the specific fields in an inventory list can vary slightly based on the industry and business size, a comprehensive and effective list typically includes the following essential elements. Think of this as a blueprint for your own spreadsheet or software setup:

| Field Name | Description & Importance (SKU) C001-RP-RD-M | Maroon V-Neck T-Shirt, Men’s Medium | 50 | 12.50 | 625.00 | WH1-A3-B2 | Global Apparel Inc. | 2023-10-26 | 15 | 7 days | 25.00 | New | Finished Goods |

| C001-RP-RD-L | Maroon V-Neck T-Shirt, Men’s Large | 45 | 12.50 | 562.50 | WH1-A3-B2 | Global Apparel Inc. | 2023-10-26 | 15 | 7 days | 25.00 | New | Finished Goods |

| C002-JE-BL-S | Blue Denim Jeans, Women’s Small | 30 | 30.00 | 900.00 | WH1-A5-C1 | Denim World Co. | 2023-11-01 | 10 | 10 days | 60.00 | New | Finished Goods |

| C003-CO-BR-OS | Brown Leather Wallet, One Size | 20 | 15.00 | 300.00 | WH1-A7-D3 | Leather Goods Ltd. | 2023-11-15 | 5 | 5 days | 35.00 | New | Finished Goods |

| RM001-FAB-COT | Cotton Fabric Roll, White | 10 | 50.00 | 500.00 | WH2-R1-S1 | Textile Suppliers | 2023-10-20 | 3 | 14 days | N/A | New | Raw Material |

| RM002-ZIP-YKK5 | YKK #5 Zippers, Black (Pack of 100) | 5 | 20.00 | 100.00 | WH2-R2-S3 | Fastener Corp. | 2023-11-05 | 2 | 7 days | N/A | New | Raw Material |

| MRO001-PRT-INK** | Printer Ink Cartridge, Black (HP 65XL) | 2 | 25.00 | 50.00 | Office-Supply | Office Depot | 2023-12-01 | 1 | 3 days | N/A | New | MRO Supply |

Let’s break down each field and its significance:

-

SKU (Stock Keeping Unit): This is a unique alphanumeric code assigned to each distinct product or product variant. It’s crucial for quick identification, tracking, and data analysis. A well-designed SKU can embed information like product type, color, size, or supplier. Example: C001-RP-RD-M (Product C001, Regular Polo, Red, Medium).

-

Item Name/Description: A clear, concise, and descriptive name of the product. This helps human readers quickly understand what the SKU refers to. Example: Maroon V-Neck T-Shirt, Men’s Medium.

-

Quantity On Hand: The current number of units of that specific item physically present in your inventory. This is the most dynamic field and requires constant updating. It’s the "bedrock" of your inventory reality.

-

Unit Cost: The cost incurred by the business to acquire one unit of the item. This includes purchase price, shipping, duties, and any other direct costs. Essential for calculating COGS and profit margins.

-

Total Value: Calculated as (Quantity On Hand x Unit Cost). This provides a real-time valuation of your inventory asset.

-

Location: Specifies the exact physical location of the item within your storage facility (e.g., warehouse, aisle, shelf, bin number). Crucial for efficient picking, packing, and physical counts. Example: WH1-A3-B2 (Warehouse 1, Aisle 3, Bin 2).

-

Supplier Information: Details about the vendor from whom the item was purchased (e.g., supplier name, contact person, order number). Useful for reordering, addressing quality issues, or negotiating terms.

-

Date Received/Last Updated: The date the inventory was last counted, received, or updated. Helps track inventory age and identify potential obsolescence.

-

Reorder Point: The minimum quantity of an item that triggers a new purchase order. This is a critical threshold to prevent stockouts while avoiding excessive inventory.

-

Lead Time: The time taken from placing an order with a supplier to receiving the goods. This helps in calculating accurate reorder points and planning.

-

Selling Price (Optional for internal lists): The price at which the item is sold to customers. While primarily a sales metric, including it here can provide quick insights into potential revenue and margin.

-

Condition: Describes the state of the item (e.g., New, Used, Damaged, Refurbished). Important for valuation and sales eligibility.

-

Category/Type: Classifies the inventory item (e.g., Raw Material, Work-in-Progress, Finished Goods, MRO). This helps in managing different inventory stages and reporting.

Types of Inventory and Their Management Nuances

Understanding the different categories of inventory is crucial, as each might have slightly different management considerations:

-

Raw Materials: Components and parts used in the manufacturing of finished products. Example: Cotton fabric, zippers, buttons.

- Nuance: Management focuses on ensuring a steady supply for production, minimizing waste, and optimizing storage for bulk items.

-

Work-in-Progress (WIP): Partially finished goods that are still undergoing the manufacturing process. Example: Cut fabric pieces waiting for assembly, unfinished furniture.

- Nuance: Tracking WIP is vital for monitoring production efficiency, identifying bottlenecks, and accurately valuing assets during the manufacturing cycle.

-

Finished Goods: Products that are complete and ready for sale to customers. Example: Packaged T-shirts, assembled furniture.

- Nuance: This is often the largest and most visible inventory. Management focuses on balancing availability with demand, preventing obsolescence, and efficient order fulfillment.

-

Maintenance, Repair, and Operating (MRO) Supplies: Items used to support the production process and general business operations but are not directly part of the final product. Example: Printer ink, cleaning supplies, spare machine parts.

- Nuance: While not directly revenue-generating, MRO supplies are critical for operational continuity. Management ensures essential items are always available to prevent operational shutdowns.

Methods for Creating and Maintaining Your Inventory List

The method you choose for managing your inventory list will depend on your business size, complexity, and budget:

-

Manual System (Spreadsheets):

- Pros: Low cost, easy to set up for small businesses with limited inventory. Widely accessible (e.g., Microsoft Excel, Google Sheets).

- Cons: Highly prone to human error, time-consuming for large inventories, difficult to scale, lacks real-time updates, limited reporting capabilities.

- Best for: Startups, very small businesses with a handful of unique products.

-

Inventory Management Software (IMS) / Enterprise Resource Planning (ERP) Systems:

- Pros: Automates tracking, provides real-time data, reduces human error, offers advanced reporting and analytics, integrates with other business functions (sales, purchasing, accounting), scalable for growth.

- Cons: Higher initial investment and ongoing costs, requires training, can have a learning curve.

- Best for: Growing businesses, medium to large enterprises, e-commerce operations, manufacturers. Popular examples include Zoho Inventory, TradeGecko (now QuickBooks Commerce), NetSuite, SAP.

-

Barcode and RFID Technology:

- Pros: Significantly increases accuracy and speed of data entry, automates physical counts, improves tracking throughout the supply chain.

- Cons: Requires investment in hardware (scanners, printers) and software integration.

- How it works: Barcodes are scanned to update inventory levels instantly. RFID tags allow for simultaneous scanning of multiple items without line-of-sight, ideal for large warehouses.

Best Practices for Inventory List Management

To truly leverage your inventory list as a strategic asset, implement these best practices:

-

Conduct Regular Audits and Cycle Counting: Don’t rely solely on digital records. Periodically (daily, weekly, or monthly) physically count a small section of your inventory (cycle counting) or perform full physical counts annually. This identifies discrepancies and ensures data accuracy.

-

Standardize Procedures: Develop clear, written procedures for every inventory-related task: receiving, stocking, picking, packing, shipping, returns, and damage reporting. Consistency is key to accuracy.

-

Train Your Staff Thoroughly: Ensure all employees involved in inventory management understand the system, procedures, and the importance of accurate data entry.

-

Implement Reorder Points and Lead Times: Use these fields to automate or semi-automate your purchasing decisions, preventing stockouts and optimizing cash flow.

-

Forecast Demand Accurately: Utilize historical sales data, market trends, and seasonal variations to predict future demand. Good forecasting reduces the risk of overstocking or understocking.

-

Minimize Obsolescence and Damage: Regularly review inventory age. Implement a "First-In, First-Out" (FIFO) system where appropriate. Establish clear protocols for handling and storing goods to prevent damage.

-

Integrate Your Inventory System: If possible, integrate your inventory management with your Point of Sale (POS) system, e-commerce platform, and accounting software for a unified view of your business operations.

-

Regularly Review and Optimize: Your inventory needs will evolve. Periodically review your inventory list fields, management processes, and software to ensure they still meet your business requirements.

Common Challenges and Solutions

Even with a robust system, challenges can arise:

- Data Inaccuracy:

- Solution: Implement frequent cycle counting, double-check entries, use barcode scanners, and provide ongoing staff training.

- Shrinkage (Theft, Damage, Loss):

- Solution: Enhance physical security, track items by location, perform regular audits, and implement clear damage reporting procedures.

- Overstocking or Understocking:

- Solution: Improve demand forecasting, refine reorder points, analyze sales data regularly, and build strong supplier relationships for faster replenishment.

- Lack of Standardization:

- Solution: Create and enforce detailed standard operating procedures (SOPs) for all inventory activities.

Conclusion

A business inventory list, far from being a mundane administrative task, is a powerful instrument that orchestrates efficiency, drives profitability, and ensures customer satisfaction. By meticulously tracking every item from its arrival to its departure, businesses gain unprecedented clarity into their operations, empowering them to make informed decisions and adapt swiftly to market changes.

Whether you’re starting with a simple spreadsheet or investing in advanced inventory management software, the commitment to maintaining an accurate and detailed inventory list is an investment in your business’s future. It’s the master key that unlocks smoother operations, healthier finances, and sustainable growth in a competitive landscape. Embrace the power of a well-managed inventory list, and watch your business thrive.