The Indispensable Compass: Navigating Business Success with an Inventory Stat Sheet

In the intricate dance of supply and demand, where every product represents both an opportunity and a potential liability, effective inventory management stands as a cornerstone of business success. For any enterprise dealing with physical goods – be it a bustling retail store, a sprawling manufacturing plant, or a nimble e-commerce operation – inventory is the lifeblood. Yet, managing this lifeblood without a clear, comprehensive view is akin to navigating a ship without a compass. This is where the Business Inventory Stat Sheet emerges as an indispensable tool, transforming raw data into actionable insights and guiding businesses toward efficiency, profitability, and sustained growth.

This article will delve into the profound importance of a well-crafted inventory stat sheet, exploring its core components, the myriad benefits it offers, and practical strategies for its implementation and maintenance.

What Exactly is a Business Inventory Stat Sheet?

At its essence, a Business Inventory Stat Sheet is a comprehensive, centralized document that provides a real-time or near real-time snapshot of a company’s entire inventory landscape. It’s more than just a list of items; it’s a dynamic data repository that encompasses critical metrics, statuses, and historical information about every product or material a business holds. Think of it as the financial statement for your physical assets, offering a detailed overview of what you have, where it is, its value, and its movement.

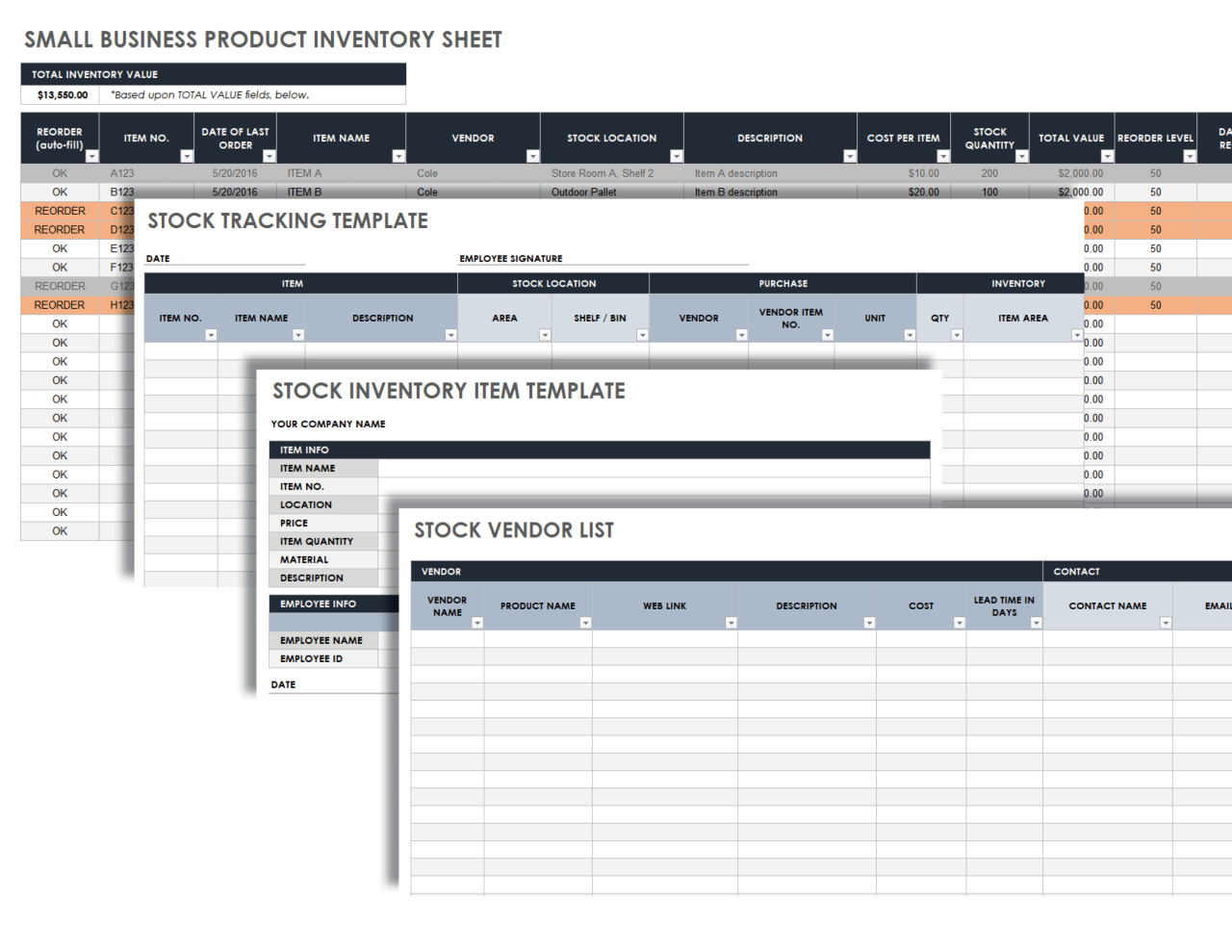

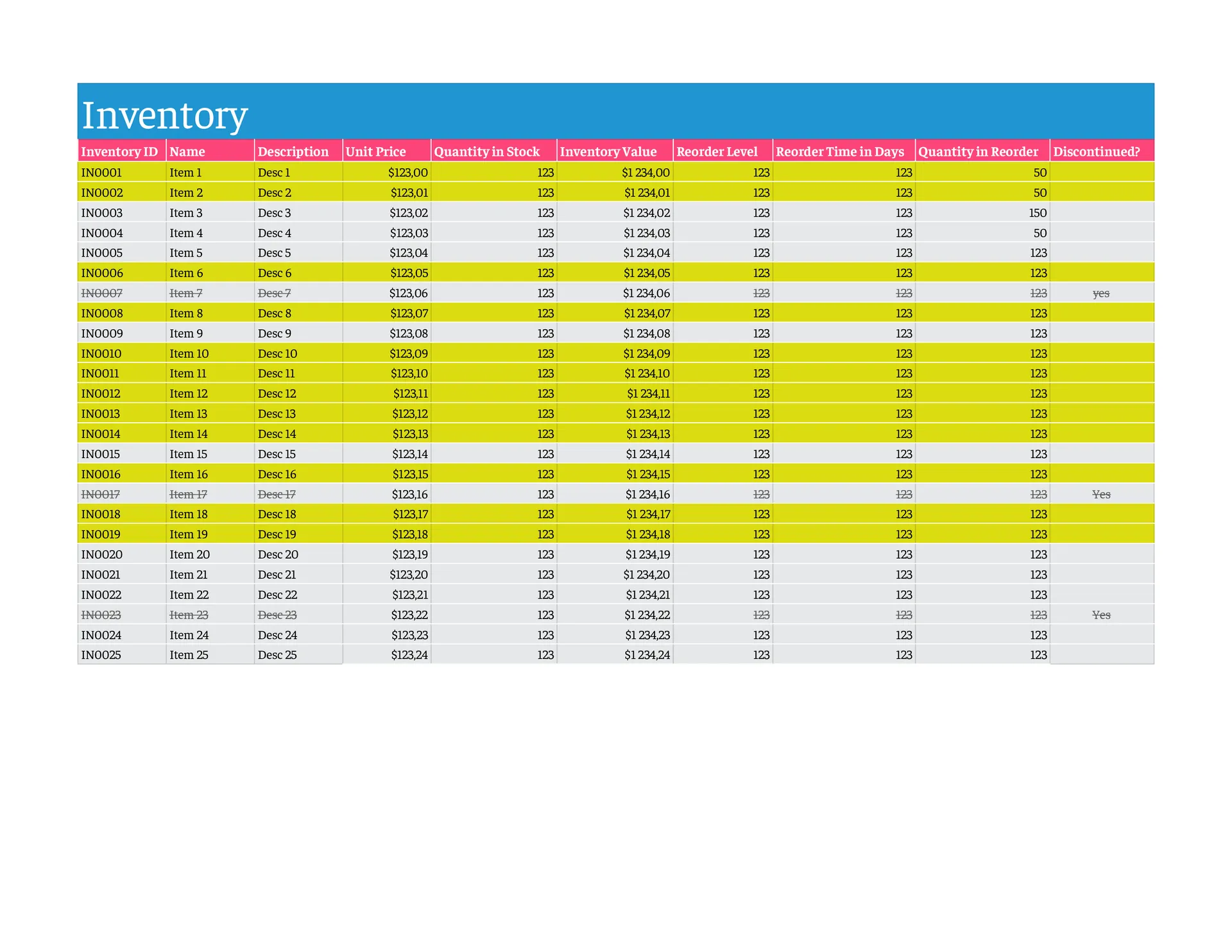

Unlike a simple stock count, a stat sheet compiles diverse data points into a cohesive report, allowing for both granular inspection of individual SKUs (Stock Keeping Units) and a high-level overview of overall inventory health. It can range from a sophisticated dashboard within an Enterprise Resource Planning (ERP) system to a meticulously maintained spreadsheet, but its fundamental purpose remains consistent: to provide clarity and control over one of a business’s most significant assets.

Why is an Inventory Stat Sheet Indispensable? The Core Benefits

The value proposition of a robust inventory stat sheet extends far beyond mere record-keeping. It underpins strategic decision-making and operational excellence, offering a multitude of benefits:

-

Cost Reduction and Optimization:

- Minimizing Holding Costs: Every item sitting in a warehouse incurs costs – storage space, insurance, security, obsolescence risk, and capital tied up. A stat sheet highlights slow-moving or obsolete inventory, prompting businesses to take action (e.g., discounts, liquidations) before these costs spiral out of control.

- Preventing Overstocking: By providing insights into demand patterns and current stock levels, the stat sheet helps prevent ordering excessive quantities, thus reducing holding costs and the risk of spoilage or obsolescence.

- Reducing Waste and Shrinkage: Accurate tracking helps identify discrepancies between recorded and physical inventory, pinpointing areas of loss due to damage, theft, or administrative errors.

-

Enhanced Operational Efficiency:

- Eliminating Stockouts: Crucially, the stat sheet provides visibility into reorder points and lead times, ensuring that popular items are replenished before they run out. This prevents lost sales and maintains customer satisfaction.

- Optimizing Warehouse Layout: By knowing exactly where each item is located and its movement frequency, businesses can optimize storage, picking, and packing processes, leading to faster fulfillment and reduced labor costs.

- Streamlining Purchasing: With precise data on what’s needed and when, purchasing decisions become proactive rather than reactive, leading to better negotiation power with suppliers and reduced expedited shipping costs.

-

Improved Cash Flow:

- Inventory represents capital. Excess inventory means capital is tied up and unavailable for other investments or operational needs. A stat sheet enables businesses to optimize inventory levels, freeing up cash flow and improving liquidity.

-

Better Decision-Making and Forecasting:

- Accurate Demand Forecasting: Historical sales data, tracked meticulously on the stat sheet, is invaluable for predicting future demand. This allows for more precise ordering, production planning, and resource allocation.

- Strategic Pricing: Understanding inventory age and holding costs can inform pricing strategies, especially for items nearing obsolescence or for maximizing profits on fast-moving goods.

- Product Lifecycle Management: Identifying products nearing the end of their lifecycle or those that are consistently underperforming allows for strategic decisions regarding discontinuation or rebranding.

-

Accurate Financial Reporting and Valuation:

- Inventory is a significant asset on a company’s balance sheet and directly impacts the Cost of Goods Sold (COGS) on the income statement. A precise stat sheet ensures accurate inventory valuation, which is critical for financial reporting, tax purposes, and investor relations.

-

Enhanced Customer Satisfaction:

- When products are consistently in stock and orders are fulfilled promptly and accurately, customer satisfaction naturally increases, fostering loyalty and positive brand perception.

-

Risk Mitigation:

- The stat sheet serves as an audit trail, helping businesses identify and mitigate risks associated with inventory loss, damage, or non-compliance with regulatory standards.

Key Components of an Effective Inventory Stat Sheet

To unlock these benefits, an inventory stat sheet must be comprehensive, capturing a variety of data points. While the specific fields may vary by industry and business size, essential components typically include:

-

Item Identification:

- SKU (Stock Keeping Unit): A unique identifier for each distinct product or variant.

- Product Name/Description: Clear, concise details of the item.

- UPC/EAN (Universal Product Code/European Article Number): Barcode information for scanning and tracking.

- Vendor/Supplier: Who the item is purchased from.

- Category/Department: For classification and reporting.

-

Quantity and Location Data:

- Quantity On Hand: The current physical count of items available.

- Quantity Reserved: Items allocated for existing orders but not yet shipped.

- Quantity In Transit: Items ordered from suppliers but not yet received.

- Quantity Available: On hand – reserved (the true available stock for new orders).

- Warehouse/Storage Location: Specific aisle, bin, or shelf where the item is stored.

-

Cost and Valuation:

- Unit Cost: The cost of acquiring one unit of the item.

- Total Inventory Value: Unit Cost x Quantity On Hand (for each SKU and overall).

- Landed Cost: Includes shipping, customs, and other costs to get the product to the warehouse.

- Selling Price: The price at which the item is sold to customers.

-

Sales and Demand Data:

- Historical Sales Data: Past sales figures (daily, weekly, monthly, yearly) to identify trends.

- Forecasted Demand: Projected future sales based on historical data, seasonality, and market trends.

- Last Sale Date: Indicates how recently an item was sold.

-

Reorder and Supply Chain Metrics:

- Reorder Point: The minimum stock level that triggers a new order.

- Reorder Quantity: The standard quantity to order when stock reaches the reorder point.

- Lead Time: The time it takes for a new order to arrive from the supplier.

- Minimum/Maximum Stock Levels: Defined thresholds for optimal inventory levels.

-

Status and Ageing:

- Date Received: When the current batch of inventory arrived.

- Inventory Age: How long items have been in stock (e.g., 0-30 days, 31-60 days, etc.), crucial for identifying slow-moving or obsolete stock.

- Condition: New, used, damaged, refurbished.

-

Performance Metrics (Calculated):

- Inventory Turnover Ratio: How many times inventory is sold and replaced over a period (Cost of Goods Sold / Average Inventory).

- Days Sales of Inventory (DSI): The average number of days it takes to convert inventory into sales.

- Fill Rate: The percentage of customer orders filled completely from existing stock.

- Stockout Rate: The percentage of times an item was out of stock when needed.

How to Implement and Maintain Your Stat Sheet

Implementing an effective inventory stat sheet requires a systematic approach:

-

Choose Your Tool:

- Spreadsheets (Excel, Google Sheets): Excellent for smaller businesses or as a starting point. They offer flexibility but can become cumbersome with scale.

- Dedicated Inventory Management Software: Offers automation, advanced reporting, barcode integration, and scalability.

- ERP Systems: Comprehensive solutions for larger businesses, integrating inventory with other business functions like sales, finance, and manufacturing.

-

Define Your Data Points: Based on your business needs, identify which of the components listed above (and any others specific to your operations) are critical to track.

-

Establish Data Entry Protocols: Consistency is key. Define who is responsible for entering and updating data, when updates should occur (e.g., daily, after every transaction), and how data accuracy will be ensured. Use barcode scanners whenever possible to minimize manual errors.

-

Conduct Initial Inventory Count: Before implementing, perform a thorough physical count of all inventory to establish an accurate baseline.

-

Integrate with Operations: Ensure the stat sheet is not a standalone document but is integrated into daily operations – receiving, picking, packing, shipping, and sales. Every inventory movement should be reflected.

-

Regular Audits and Updates (Cycle Counting): Don’t wait for annual inventory. Implement regular cycle counting – counting a small section of inventory daily or weekly – to catch discrepancies early and maintain accuracy.

-

Train Your Team: Ensure everyone who interacts with inventory understands the importance of the stat sheet and how to use the chosen system correctly.

Common Challenges and Solutions

- Data Inaccuracy: The biggest enemy of an inventory stat sheet. Solution: Implement strict data entry protocols, use automation (scanners, integrated software), conduct frequent cycle counts, and perform regular reconciliation.

- Time-Consuming Maintenance: Manual updates can be laborious. Solution: Invest in software that automates data capture and updates, freeing up staff for more analytical tasks.

- Resistance to Change: Employees may be hesitant to adopt new systems. Solution: Provide thorough training, highlight the benefits (e.g., reduced workload, fewer errors), and involve key users in the selection and implementation process.

- Lack of Integration: If the stat sheet isn’t connected to sales or purchasing, it loses effectiveness. Solution: Choose integrated software solutions or develop robust processes for data transfer between systems.

Conclusion

In today’s competitive landscape, relying on intuition or outdated methods for inventory management is a recipe for inefficiency and lost profits. The Business Inventory Stat Sheet is far more than a simple record; it is a dynamic, strategic asset that empowers businesses with unparalleled visibility and control over their physical goods. By meticulously tracking, analyzing, and acting upon the data it provides, companies can reduce costs, optimize operations, improve cash flow, enhance customer satisfaction, and make more informed, forward-looking decisions.

Embracing the power of a well-maintained inventory stat sheet is not just about managing stock; it’s about navigating the complexities of the market with confidence, ensuring that your business is always equipped with the right products, in the right place, at the right time, to meet demand and achieve sustainable success. It is, truly, the indispensable compass for modern commerce.