The Indispensable Backbone: Mastering Your Business with an Effective Inventory Sheet

In the dynamic world of business, where efficiency and profitability often hinge on meticulous management, one tool stands out as a fundamental cornerstone: the business inventory sheet. Far from being a mere checklist, an effectively managed inventory sheet is the unsung hero that drives operational excellence, optimizes financial health, and empowers strategic decision-making. Whether you’re a small e-commerce startup or a sprawling manufacturing enterprise, understanding, implementing, and maintaining a robust inventory sheet is not just good practice—it’s imperative for survival and growth.

What Exactly is a Business Inventory Sheet?

At its core, a business inventory sheet is a detailed record of all the goods, products, and materials a company possesses. It’s a comprehensive document that meticulously tracks items from the moment they enter your possession (as raw materials, components, or finished goods from a supplier) until they leave (as sold products, consumed materials, or disposed items). Think of it as a living ledger for your physical assets, providing a snapshot of what you have, where it is, and often, its value.

Traditionally, this might have been a physical ledger or a basic spreadsheet. Today, while advanced software systems have automated much of this, the underlying principles and data points of an inventory sheet remain critical. It’s the foundational data structure that even the most sophisticated inventory management systems rely upon.

Why is an Inventory Sheet Critical for Your Business?

The benefits of a well-maintained inventory sheet ripple through every facet of a business, contributing significantly to its overall health and competitive edge.

-

Cost Control and Reduction:

- Preventing Overstocking: Holding excess inventory ties up capital, incurs storage costs (warehousing, utilities, insurance), and increases the risk of obsolescence or spoilage. An inventory sheet helps you identify slow-moving items and optimize reorder points.

- Avoiding Understocking (Stockouts): Running out of popular products leads to lost sales, dissatisfied customers, and potential damage to your brand reputation. Accurate tracking ensures you reorder before stock levels hit critical lows.

- Minimizing Waste and Spoilage: For perishable goods or items with expiry dates, an inventory sheet allows for "first-in, first-out" (FIFO) management, reducing waste.

- Identifying Shrinkage: Discrepancies between your physical count and your sheet can highlight theft, damage, or administrative errors, allowing you to address them promptly.

-

Optimized Operations and Efficiency:

- Streamlined Order Fulfillment: Knowing exactly where each item is located in your warehouse dramatically speeds up picking and packing processes.

- Improved Production Planning: Manufacturers rely on accurate raw material and component inventory data to schedule production runs efficiently, avoiding costly delays.

- Better Resource Allocation: Understanding inventory levels helps allocate labor and equipment more effectively.

-

Enhanced Customer Satisfaction:

- Reliable Product Availability: Customers expect products to be in stock. An accurate inventory sheet helps ensure you meet those expectations.

- Faster Delivery Times: Efficient fulfillment directly translates to quicker delivery, a key differentiator in today’s market.

- Accurate Order Information: Businesses can confidently tell customers if an item is in stock and when it will ship.

-

Improved Financial Reporting and Decision Making:

- Accurate Asset Valuation: Inventory is a significant asset on the balance sheet. Proper valuation is crucial for financial statements, loan applications, and investor relations.

- Cost of Goods Sold (COGS): An inventory sheet is essential for calculating COGS accurately, which directly impacts gross profit.

- Budgeting and Forecasting: Historical inventory data informs future purchasing decisions, sales forecasts, and overall budget planning.

- Tax Compliance: Accurate inventory records are often required for tax purposes.

-

Better Strategic Planning:

- Identifying Trends: Analyzing inventory data over time can reveal sales patterns, seasonality, and product popularity, informing marketing strategies and product development.

- Supplier Management: Understanding which suppliers deliver on time and with quality goods can improve procurement strategies.

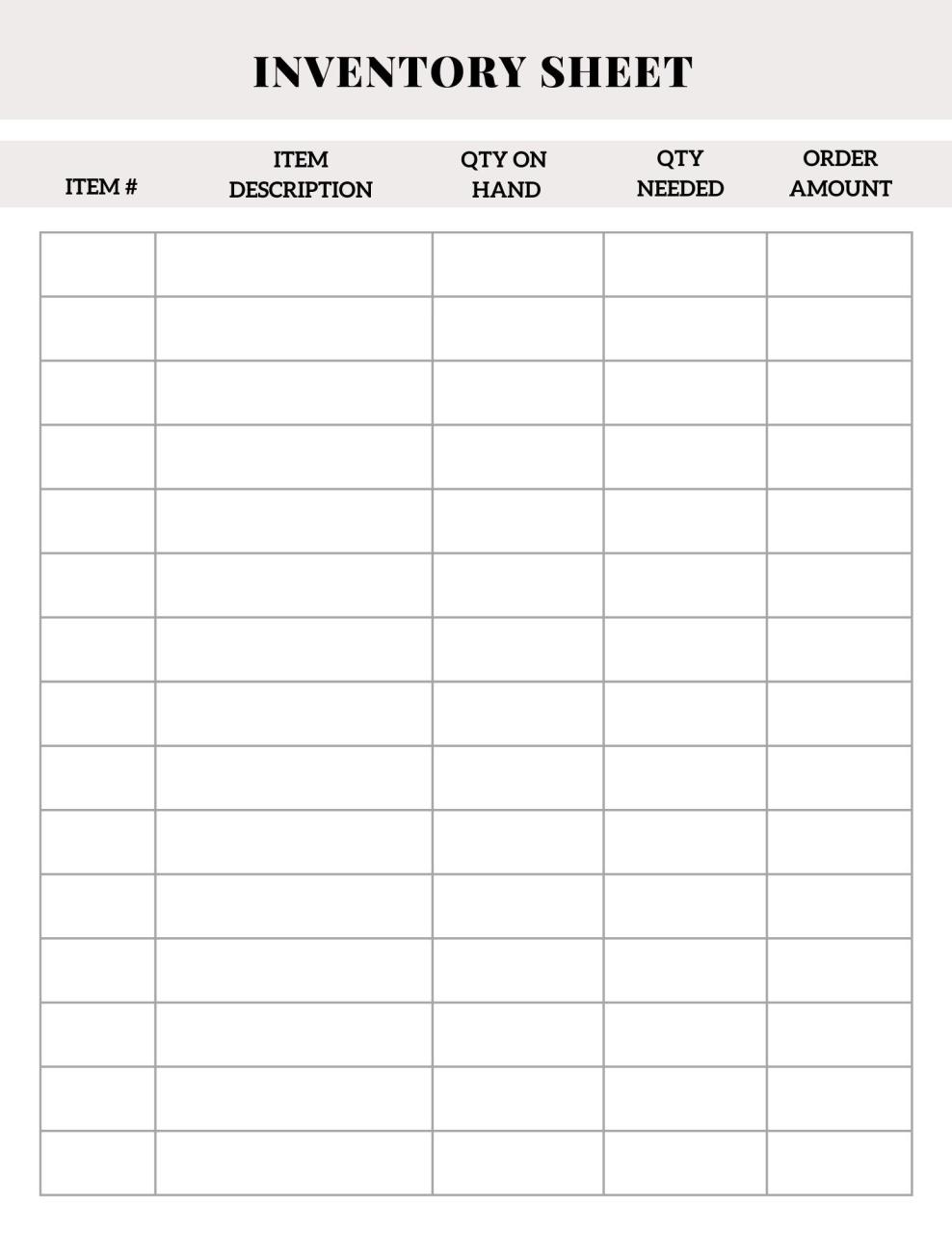

Essential Components of an Effective Inventory Sheet

While the specific fields may vary slightly depending on the industry and business type, a robust inventory sheet typically includes the following crucial data points:

- Item ID / SKU (Stock Keeping Unit): A unique alphanumeric code for each distinct product or item. This is critical for accurate identification and tracking.

- Item Name / Description: A clear, concise name and brief description of the item.

- Category / Type: Grouping items (e.g., electronics, apparel, raw material A) helps with analysis and organization.

- Supplier Information: Name, contact details, and sometimes lead time for reordering from specific suppliers.

- Unit of Measure: How the item is counted (e.g., pieces, units, liters, meters, kilograms, boxes).

- Quantity On Hand (QOH): The current physical count of the item in stock. This is the most dynamic and frequently updated field.

- Location: Precise physical location within your warehouse or storage facility (e.g., Aisle 3, Shelf B, Bin 7). This is vital for efficient picking.

- Unit Cost: The cost to your business for acquiring or producing one unit of the item.

- Total Value: Calculated as Quantity On Hand * Unit Cost, providing the current monetary value of the stock for that item.

- Reorder Point: The minimum quantity of an item that triggers a new purchase order to replenish stock.

- Lead Time (Days): The typical time it takes for a new order to arrive from the supplier after it’s placed.

- Last Updated / Date Received: The date the item’s quantity was last adjusted or the date a new shipment was received. This helps with auditing and tracking.

- Status: Active, Discontinued, Obsolete, On Order, etc.

- Notes: Any additional relevant information, such as special handling instructions, quality control issues, or batch numbers.

Types of Inventory to Track

Businesses often deal with different categories of inventory, each requiring careful tracking:

- Raw Materials: Basic components or ingredients used in the manufacturing process (e.g., wood for furniture, fabric for clothing).

- Work-in-Progress (WIP): Partially finished goods that are still undergoing production (e.g., a car on the assembly line, a shirt that’s been cut but not sewn).

- Finished Goods: Products that are complete and ready for sale to customers (e.g., a completed chair, a packaged shirt).

- MRO (Maintenance, Repair, and Operating Supplies): Items used in the business operations but not part of the final product (e.g., office supplies, cleaning supplies, spare parts for machinery).

Methods of Inventory Tracking

Two primary methods underpin how businesses keep their inventory sheets updated:

-

Periodic Inventory System:

- Inventory levels are updated periodically (e.g., weekly, monthly, quarterly) through a physical count.

- Suitable for smaller businesses with low transaction volumes or those with a small number of high-value items.

- Simpler to implement but offers less real-time visibility and makes it harder to detect shrinkage quickly.

-

Perpetual Inventory System:

- Inventory records are updated continuously in real-time as items are received, sold, or moved.

- Relies on technology like barcode scanners, POS systems, and dedicated inventory management software.

- Provides accurate, up-to-the-minute data, making it ideal for businesses with high transaction volumes and complex operations.

- More costly to implement initially but offers superior control and insights.

Implementing and Maintaining Your Inventory Sheet

Setting up an inventory sheet is just the first step; consistent maintenance is key to its effectiveness.

-

Choose the Right Tool:

- Manual Sheets/Notebooks: Very small businesses or initial stages. Prone to error and difficult to scale.

- Spreadsheets (Excel, Google Sheets): Excellent for small to medium-sized businesses. Offer flexibility, formulas for automation (e.g., calculating total value), and relatively low cost. This is where most businesses start.

- Dedicated Inventory Management Software/ERP Systems: For larger businesses, multiple locations, high volumes, or complex needs. Offers advanced features like automation, reporting, integrations with POS/e-commerce, and multi-user access.

-

Conduct an Initial Physical Count: Before anything else, perform a thorough physical count of all inventory. This forms your baseline data.

-

Standardize Your Data: Ensure consistent naming conventions, SKU formats, and units of measure. Inconsistency leads to errors.

-

Establish Clear Processes: Define who is responsible for updating the sheet, when updates occur (e.g., every sale, every delivery), and how discrepancies are handled.

-

Train Your Staff: Everyone who interacts with inventory (receiving, sales, shipping, production) must understand the system and their role in maintaining its accuracy.

-

Regular Audits and Reconciliation: Even with perpetual systems, periodic physical counts (cycle counts or annual full counts) are crucial to reconcile against your sheet and identify discrepancies. Investigate significant differences.

Common Challenges and How to Overcome Them

Even with the best intentions, maintaining an accurate inventory sheet can be challenging:

- Data Inaccuracy: Human error, misplaced items, or unrecorded transactions.

- Solution: Implement barcode scanning, automate wherever possible, conduct regular cycle counts, and enforce strict protocols.

- Lack of Standardization: Different departments using different terminology or tracking methods.

- Solution: Develop and enforce a company-wide inventory policy and data standards.

- Scalability Issues: A basic spreadsheet becoming unwieldy as the business grows.

- Solution: Be prepared to transition to more robust software as your inventory volume and complexity increase.

- Resistance to Change: Staff hesitant to adopt new tracking methods.

- Solution: Provide thorough training, explain the "why" behind the changes, and demonstrate how new systems simplify their work.

- Discrepancies Between Systems: If using multiple systems (e.g., separate POS and inventory sheets), data can get out of sync.

- Solution: Seek integrated solutions or implement rigorous reconciliation processes between systems.

Beyond the Basic Sheet: Advanced Considerations

As your business matures, your inventory management can evolve beyond a simple sheet:

- Integration with Other Systems: Connect your inventory data to your Point of Sale (POS), e-commerce platform, Enterprise Resource Planning (ERP), and accounting software for seamless data flow.

- Demand Forecasting: Use historical sales data from your inventory records to predict future demand and optimize purchasing.

- ABC Analysis: Categorize inventory items by their value and importance (A-items: high value, B-items: medium, C-items: low value) to prioritize management efforts.

- Safety Stock: Maintain a buffer of inventory to guard against unexpected spikes in demand or supply chain disruptions.

- Leveraging Technology: Explore barcode/QR code scanning, RFID (Radio-Frequency Identification), IoT sensors, and even AI-driven analytics for real-time tracking and predictive insights.

Conclusion

The business inventory sheet, in its various forms, is far more than a simple record-keeping device; it is a powerful strategic tool. It provides the clarity and control necessary to navigate the complexities of supply and demand, optimize financial performance, and ultimately, deliver superior value to your customers. Investing time and effort into creating and meticulously maintaining an accurate inventory sheet is not an expense; it’s an investment in the efficiency, profitability, and long-term sustainability of your business. Embrace it as the indispensable backbone it is, and watch your operations transform.