Optimizing Operations: The Indispensable Role of Business Inventory Platform Websites

In the fast-paced, interconnected world of modern commerce, managing inventory effectively is no longer just about knowing what you have in stock. It’s a critical strategic function that underpins operational efficiency, customer satisfaction, and ultimately, profitability. From a small e-commerce startup to a multinational manufacturing giant, the challenges of tracking goods, predicting demand, and preventing costly errors are immense. This is where business inventory platform websites emerge as indispensable tools, transforming chaotic stockrooms into streamlined, data-driven operational hubs.

The Evolution of Inventory Management: From Ledgers to Cloud Intelligence

For centuries, inventory management was a manual, painstaking process. Businesses relied on physical counts, ledger books, and later, cumbersome spreadsheets to keep track of their goods. This approach was inherently prone to human error, incredibly time-consuming, and offered little to no real-time insight. Decisions were often made based on outdated information, leading to costly mistakes like stockouts, overstocking, and inefficient ordering.

The digital revolution brought about a significant shift, introducing standalone software solutions that automated some aspects of tracking. However, these often required on-premise installation, lacked integration capabilities, and were inaccessible outside the physical office. The true paradigm shift arrived with the advent of the internet and cloud computing. Business inventory platform websites, hosted online and accessible from anywhere with an internet connection, have revolutionized how companies manage their assets. These platforms offer a centralized, real-time view of inventory, integrating seamlessly with other critical business functions and providing the intelligence needed to thrive in today’s competitive landscape.

Why Modern Businesses Can’t Afford Manual Methods

The complexities of modern supply chains and customer expectations make manual inventory management an untenable strategy. The costs and inefficiencies associated with outdated methods are substantial:

- Human Error: Manual data entry is a breeding ground for mistakes – miscounts, incorrect entries, and lost paperwork can lead to a ripple effect of errors throughout the supply chain.

- Lack of Real-time Visibility: Without an automated system, businesses operate in the dark, unable to know the exact quantity or location of their stock at any given moment. This leads to missed sales opportunities due to perceived stockouts or delayed fulfillment.

- Stockouts and Lost Sales: Running out of popular items disappoints customers, drives them to competitors, and results in direct revenue loss.

- Overstocking and Carrying Costs: Holding too much inventory ties up capital, incurs storage fees, and increases the risk of obsolescence or damage. This directly impacts cash flow and profitability.

- Inefficient Ordering: Without accurate data, purchasing decisions are based on guesswork, leading to either excessive orders or last-minute, expensive rush orders.

- Time Consumption: Employees spend valuable time on manual counts, data entry, and searching for items, diverting resources from more strategic tasks.

- Poor Data for Decision Making: Manual systems provide fragmented, historical data, making it impossible to perform accurate demand forecasting, trend analysis, or strategic planning.

- Difficulty with Multi-location Management: Businesses with multiple warehouses, retail stores, or distribution centers face an insurmountable challenge trying to unify inventory data manually.

These challenges highlight that an inventory management platform is not a luxury, but a fundamental necessity for sustainable growth and operational excellence.

Core Features of a Robust Inventory Platform Website

A comprehensive business inventory platform website offers a suite of functionalities designed to address every aspect of inventory management:

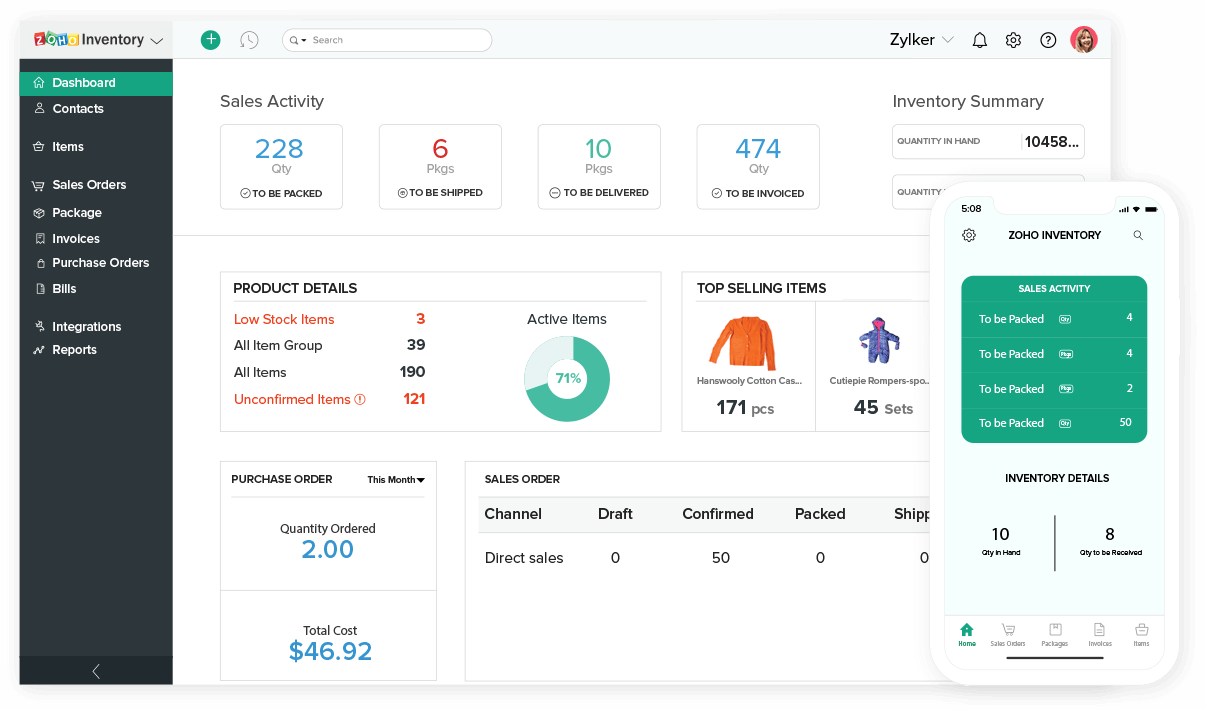

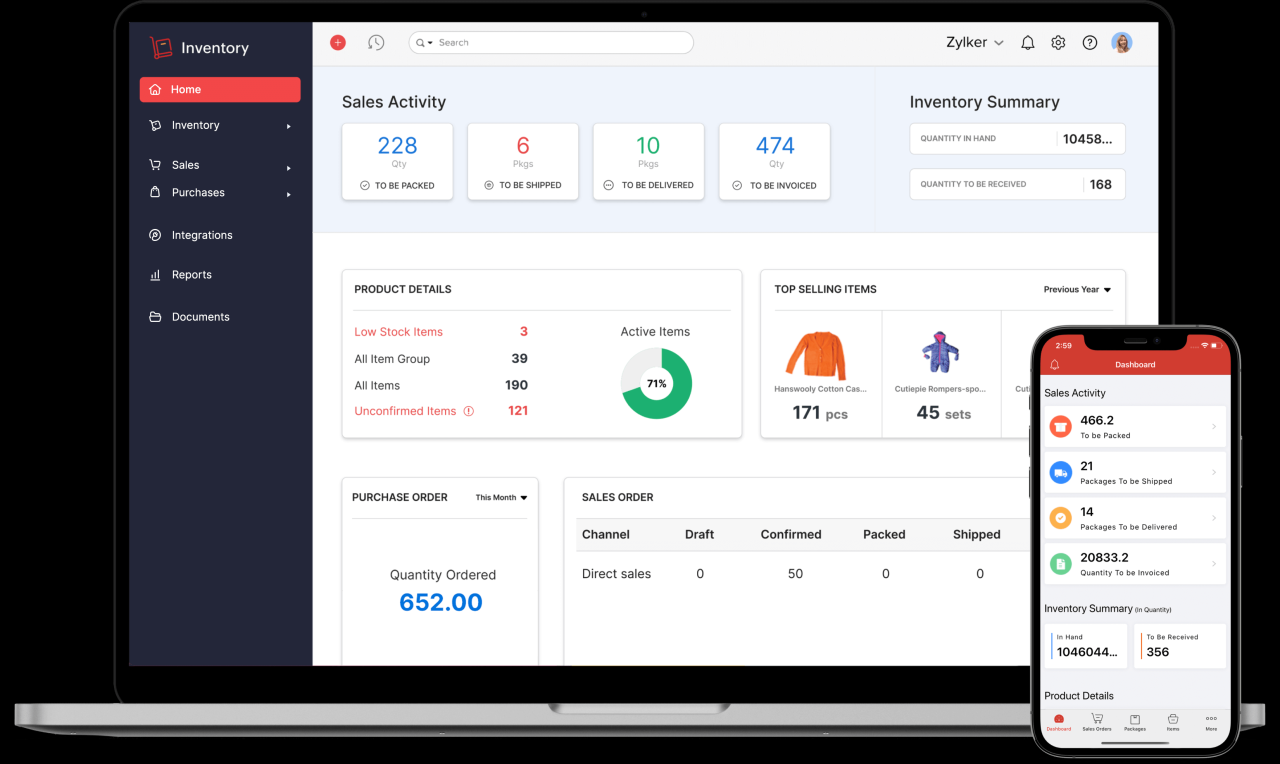

- Real-time Tracking & Centralized Database: The cornerstone feature, providing an up-to-the-minute view of all inventory across all locations from a single dashboard. Every item’s movement – from receipt to sale – is recorded instantly.

- Order Management: Streamlines the entire order lifecycle, from creating purchase orders (POs) for suppliers to processing sales orders (SOs) for customers. It often includes features for order fulfillment, shipping integration, and backorder management.

- Warehouse & Multi-Location Management: Enables businesses to organize and track inventory across multiple warehouses, retail stores, or distribution centers. This includes bin location tracking, inter-warehouse transfers, and zone management.

- Barcode Scanning & RFID Integration: Accelerates inventory counts, receiving, picking, and packing processes while drastically reducing human error. Mobile apps often allow for scanning directly from smartphones or dedicated handheld devices.

- Supplier & Vendor Management: Keeps detailed records of suppliers, including contact information, lead times, pricing, and purchase history, facilitating more efficient procurement.

- Reporting & Analytics: Generates insightful reports on inventory turnover, sales trends, stock levels, cost of goods sold (COGS), and profitability. Advanced platforms offer customizable dashboards and predictive analytics.

- Integrations with Other Business Systems: Seamlessly connects with essential software like:

- E-commerce Platforms: (Shopify, WooCommerce, Magento) to sync online sales and update stock levels automatically.

- POS Systems: (Square, Lightspeed) for real-time updates from brick-and-mortar sales.

- Accounting Software: (QuickBooks, Xero, SAP) to automate financial entries related to inventory.

- Shipping Carriers & Fulfillment Services: (FedEx, UPS, ShipStation) to streamline the shipping process.

- CRM Systems: To link customer orders with inventory.

- Inventory Optimization: Features like automated reorder points, safety stock calculations, and demand forecasting tools help businesses maintain optimal stock levels, preventing both stockouts and overstocking.

- Kitting & Bundling: Allows businesses to create product kits or bundles from individual components, accurately tracking the stock levels of both the components and the finished kits.

- Lot & Serial Number Tracking: Essential for industries requiring detailed traceability (e.g., food, pharmaceuticals, electronics) for quality control, warranty, or recall purposes.

Key Benefits for Businesses

Implementing a business inventory platform website delivers a multitude of advantages that directly impact a company’s bottom line and operational efficiency:

- Enhanced Accuracy & Reduced Errors: Automation eliminates manual data entry mistakes, leading to highly accurate stock counts and fewer discrepancies.

- Significant Cost Reduction:

- Lower Carrying Costs: Optimizing stock levels reduces storage expenses, insurance, and the risk of obsolescence.

- Reduced Waste & Shrinkage: Better tracking minimizes lost, damaged, or expired goods.

- Optimized Ordering: Prevents costly over-ordering or expensive last-minute expedited shipments.

- Improved Cash Flow: Less capital tied up in excess inventory means more liquidity for other investments.

- Improved Operational Efficiency:

- Automated Processes: Tasks like stock counts, order processing, and reordering are automated, freeing up staff for higher-value activities.

- Faster Fulfillment: Accurate stock data and streamlined picking/packing processes lead to quicker order processing and delivery.

- Time Savings: Employees spend less time searching for items or manually updating records.

- Better Decision-Making: Access to real-time data and comprehensive reports empowers managers to make informed decisions regarding purchasing, pricing, sales strategies, and promotions.

- Increased Customer Satisfaction: Fewer stockouts, faster delivery times, and accurate order fulfillment lead to happier, more loyal customers.

- Scalability: These platforms are designed to grow with the business, easily accommodating increased inventory volumes, new product lines, or additional locations without needing a complete overhaul.

- Compliance & Auditing: Detailed transaction histories and robust reporting make it easier to comply with industry regulations and simplify auditing processes.

- Strategic Advantage: Businesses with superior inventory management can respond more quickly to market changes, capitalize on trends, and offer a more reliable service than competitors.

Who Needs an Inventory Platform Website?

Virtually any business that holds physical goods stands to benefit:

- Retailers (Online & Brick-and-Mortar): Manage products across various sales channels and locations.

- E-commerce Businesses: Critical for syncing website stock with actual inventory and automating fulfillment.

- Wholesalers & Distributors: Optimize complex supply chains, manage large volumes, and handle multiple vendors/customers.

- Manufacturers: Track raw materials, work-in-progress, and finished goods, and manage bills of materials.

- Service-Based Businesses: That rely on parts, supplies, or equipment for their operations (e.g., HVAC, plumbing, IT repair).

- Small, Medium, and Large Enterprises: Platforms cater to varying scales, offering solutions from basic tracking to enterprise-level ERP integration.

Choosing the Right Platform: Key Considerations

Selecting the ideal inventory platform requires careful evaluation of a business’s unique needs:

- Business Size & Industry: Platforms are often tailored for small businesses, mid-market, or enterprise-level operations, and some specialize in specific industries (e.g., food, automotive).

- Scalability: Ensure the platform can accommodate future growth in inventory volume, product lines, and locations without requiring a migration to a new system.

- Integration Capabilities: The platform’s ability to seamlessly integrate with existing POS, e-commerce, accounting, and CRM systems is paramount to avoiding data silos.

- Key Features Required: Prioritize features essential for your operations (e.g., multi-location, kitting, lot tracking, specific reporting).

- User Interface (UI) & User Experience (UX): An intuitive, easy-to-use interface minimizes the learning curve and boosts employee adoption.

- Reporting & Analytics: Assess the depth and customizability of reporting tools to ensure they provide the insights you need.

- Customer Support & Training: Robust support and comprehensive training resources are vital for smooth implementation and ongoing usage.

- Cost: Evaluate pricing models (subscription fees, per-user costs, setup fees) against the value and ROI the platform offers.

- Security: Ensure the platform employs strong data encryption, backup procedures, and access controls to protect sensitive inventory and business data.

- Mobile Accessibility: The ability to manage inventory on the go via mobile devices or tablets can be a significant advantage.

Implementation and Future Trends

Implementing an inventory platform requires careful planning, data migration, and thorough staff training. A phased rollout can help minimize disruption. The benefits, however, quickly outweigh the initial effort.

Looking ahead, inventory management platforms are poised for even greater sophistication. The integration of Artificial Intelligence (AI) and Machine Learning (ML) will enhance demand forecasting, optimize reorder points, and even suggest pricing strategies. Internet of Things (IoT) devices, such as smart shelves and sensors, will enable truly autonomous inventory tracking. Blockchain technology could offer unprecedented transparency and traceability across complex supply chains. Furthermore, the increasing adoption of robotics and automation in warehouses will necessitate even tighter integration with inventory management systems, creating highly efficient and responsive supply chains.

Conclusion

Business inventory platform websites have transcended their basic function of mere stock-keeping to become strategic assets in the modern economy. They offer the power of real-time visibility, automation, and data-driven insights, transforming the way businesses operate. By mitigating errors, reducing costs, improving efficiency, and enhancing customer satisfaction, these platforms empower companies to navigate the complexities of supply chain management with confidence.

In an era where agility and precision are paramount, investing in a robust inventory platform is not just an operational upgrade; it’s a fundamental commitment to a business’s long-term success, resilience, and competitive edge. For any enterprise dealing with physical goods, embracing this technology is no longer an option, but an imperative for sustainable growth and thriving in the digital age.