Optimizing Operations: The Indispensable Role of Business Inventory Management Software

In the intricate dance of modern commerce, inventory stands as both a vital asset and a significant liability. Too much inventory ties up capital, incurs storage costs, and risks obsolescence. Too little leads to stockouts, missed sales opportunities, and disgruntled customers. Striking the perfect balance is a monumental challenge that has plagued businesses for centuries. In today’s fast-paced, globalized economy, manual inventory management is no longer merely inefficient; it’s a recipe for disaster. This is where Business Inventory Management Software (IMS) emerges not just as a tool, but as a critical strategic imperative for companies of all sizes.

This comprehensive article will delve into the multifaceted world of business inventory management software, exploring its core functionalities, the profound benefits it offers, key considerations for selection, best practices for implementation, and a glimpse into its future.

The Quagmire of Manual Inventory Management

Before understanding the solution, it’s crucial to grasp the depth of the problem. Without dedicated software, inventory management often relies on a patchwork of spreadsheets, paper records, and sporadic physical counts. This manual approach is fraught with pitfalls:

- Inaccuracy: Human error is inevitable, leading to discrepancies between recorded and actual stock levels.

- Lack of Real-Time Visibility: Data is often outdated, making it impossible to know current stock levels, locations, or movement.

- Inefficiency: Tasks like counting, ordering, and tracking are labor-intensive and time-consuming.

- Poor Decision-Making: Without accurate data, forecasting is speculative, leading to either overstocking or understocking.

- Hidden Costs: Obsolete inventory, excessive carrying costs, and lost sales due to stockouts erode profitability.

- Scalability Issues: As a business grows, manual systems quickly become unmanageable and break down.

These challenges directly impact a company’s bottom line, customer satisfaction, and long-term sustainability.

What is Business Inventory Management Software?

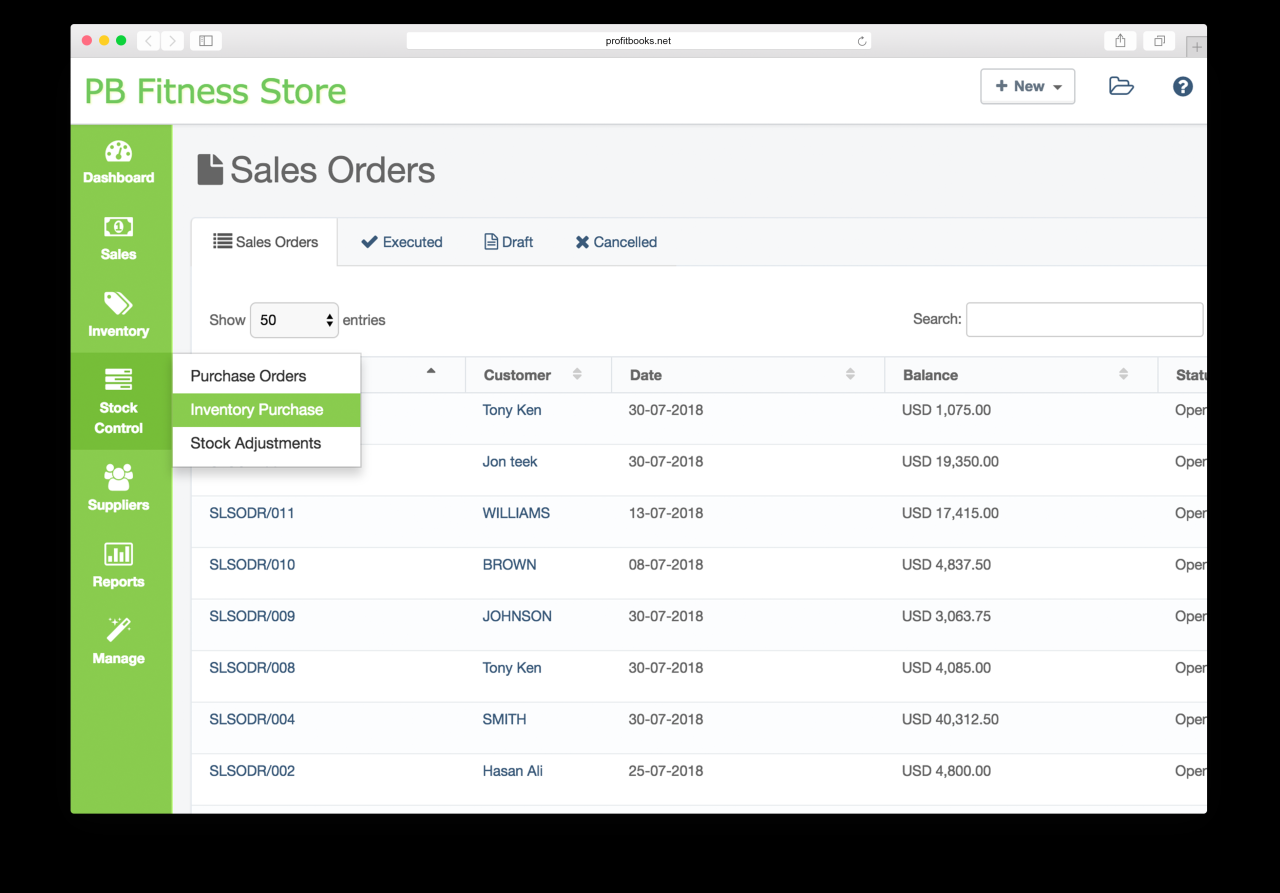

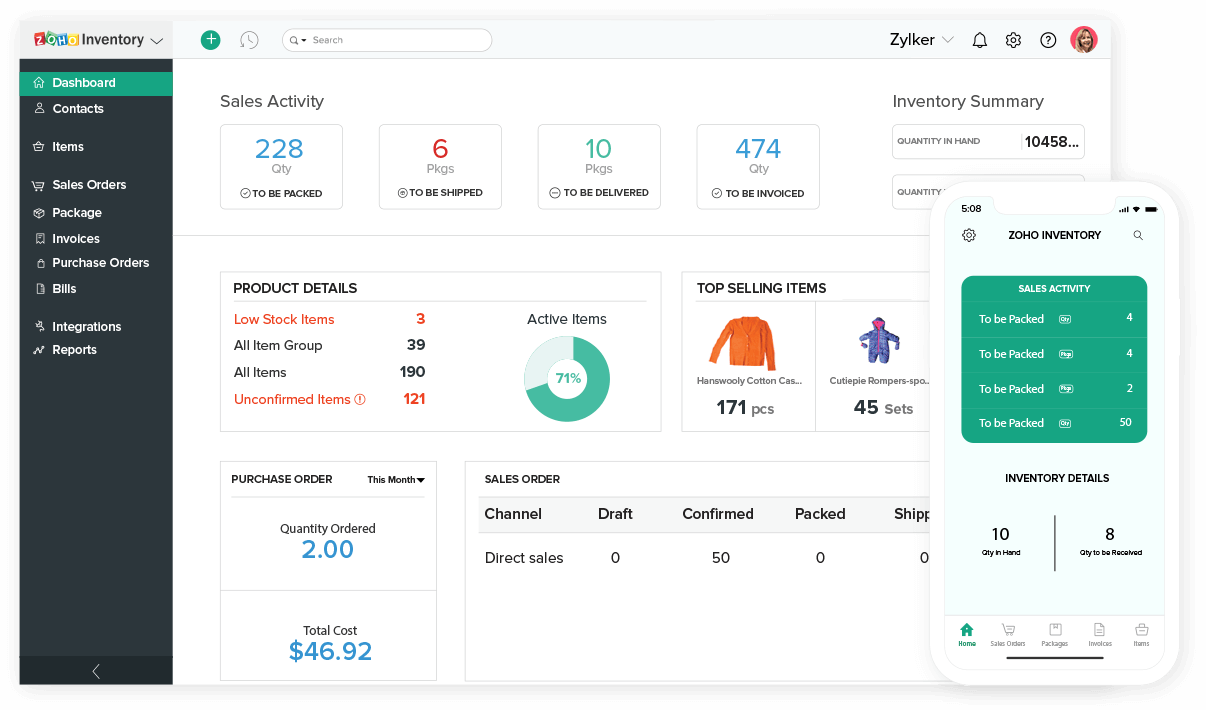

Business Inventory Management Software is a digital solution designed to track, manage, and organize a company’s goods, materials, and products from acquisition to sale. It provides a centralized system for monitoring inventory levels, locations, movements, and related data, automating many of the tasks traditionally performed manually. More than just a digital ledger, modern IMS integrates various business functions to provide a holistic view of the supply chain.

Core Functionalities and Key Features

A robust IMS typically offers a suite of features designed to streamline inventory operations:

-

Real-time Tracking and Visibility: This is perhaps the most fundamental feature. IMS provides an immediate and accurate overview of all inventory items, including their quantity, location (warehouse, shelf, bin), status (available, on order, reserved, in transit), and movement history. This eliminates guesswork and empowers informed decision-making.

-

Automated Reordering and Forecasting: Leveraging historical sales data, seasonal trends, and supplier lead times, the software can automatically generate purchase orders when stock levels hit predefined reorder points. Advanced systems use sophisticated algorithms for demand forecasting, optimizing stock levels and minimizing the risk of stockouts or overstocking.

-

Warehouse Management Capabilities (WMS Integration): Many IMS solutions include or integrate with Warehouse Management Systems (WMS) features. This allows for optimized warehouse layouts, efficient picking and packing routes, putaway strategies, and accurate tracking of items within specific warehouse locations.

-

Multi-Location and Multi-Channel Management: For businesses operating across multiple warehouses, retail stores, or e-commerce platforms, IMS centralizes inventory data from all channels. This ensures consistent stock levels, prevents overselling, and facilitates efficient fulfillment from the nearest or most cost-effective location.

-

Barcode and RFID Support: Integration with barcode scanners and RFID technology enables rapid and accurate data capture for receiving, moving, and shipping inventory. This drastically reduces manual entry errors and speeds up operational processes.

-

Lot and Serial Number Tracking: Essential for industries requiring strict traceability (e.g., food, pharmaceuticals, electronics), this feature tracks individual items or batches of products throughout their lifecycle, facilitating recalls, warranty management, and quality control.

-

Reporting and Analytics: IMS transforms raw inventory data into actionable insights. Customizable reports provide information on sales trends, inventory turnover rates, carrying costs, slow-moving items, supplier performance, and more. These analytics are crucial for strategic planning and continuous improvement.

-

Integration Capabilities: A truly powerful IMS doesn’t operate in a vacuum. It seamlessly integrates with other critical business systems such as:

- Enterprise Resource Planning (ERP): For a unified view of finance, sales, and operations.

- Customer Relationship Management (CRM): To link inventory availability with customer orders and preferences.

- E-commerce Platforms: To automatically update stock levels on online stores after sales.

- Point of Sale (POS) Systems: For real-time inventory updates from physical retail locations.

- Accounting Software: To manage inventory valuation and cost of goods sold.

-

Return Management (RMAs): Streamlines the process of handling product returns, ensuring returned items are correctly re-stocked, repaired, or discarded, and that inventory records are accurately updated.

The Profound Benefits of Adopting IMS

Implementing an effective inventory management software solution yields a multitude of advantages that ripple across an entire organization:

-

Reduced Costs and Increased Profitability:

- Lower Carrying Costs: By optimizing stock levels, businesses reduce expenses related to storage, insurance, security, and obsolescence.

- Minimized Stockouts: Accurate forecasting and automated reordering prevent lost sales and maintain customer loyalty.

- Reduced Waste and Obsolescence: Identifying slow-moving or expiring goods allows for proactive measures like promotions or liquidation.

- Optimized Purchasing: Better data leads to more strategic purchasing decisions, potentially unlocking bulk discounts or better supplier terms.

-

Enhanced Efficiency and Productivity:

- Automated Processes: Eliminates manual data entry, reducing human error and freeing up staff for more value-added tasks.

- Faster Operations: Streamlined receiving, picking, packing, and shipping processes speed up order fulfillment.

- Improved Workflow: Clearer data and automated alerts ensure smoother operations and fewer bottlenecks.

-

Improved Accuracy and Data Reliability:

- Real-Time Data: Provides a single, accurate source of truth for all inventory-related information.

- Reduced Errors: Automation and barcode scanning significantly decrease the likelihood of counting and recording mistakes.

-

Better Decision-Making:

- Actionable Insights: Comprehensive reports and analytics empower management to make data-driven decisions regarding purchasing, pricing, marketing, and sales strategies.

- Strategic Planning: Understanding inventory trends allows for more effective long-term business planning.

-

Increased Customer Satisfaction:

- Fewer Stockouts: Ensures products are available when customers want them.

- Faster Fulfillment: Efficient operations lead to quicker order processing and delivery.

- Accurate Orders: Reduces shipping errors, enhancing customer trust.

-

Scalability and Growth Support: IMS provides the infrastructure needed for businesses to grow without their inventory operations becoming a bottleneck. It can adapt to increased product lines, sales volumes, and additional locations.

-

Compliance and Auditing: For regulated industries, IMS provides a clear audit trail of inventory movement, batch numbers, and expiry dates, simplifying compliance and recall procedures.

Choosing the Right Inventory Management Software

Selecting the ideal IMS is a critical decision that requires careful consideration:

- Assess Your Specific Needs: What are your business size, industry, product complexity, existing systems, and budget? Do you need multi-location support, e-commerce integration, or advanced manufacturing features?

- Scalability: Choose a solution that can grow with your business. Can it handle increased inventory volume, new product lines, or additional warehouses?

- Integration Capabilities: Ensure the software can seamlessly connect with your existing ERP, CRM, accounting, and e-commerce platforms.

- User-Friendliness: The interface should be intuitive and easy for your team to learn and use, minimizing training time and maximizing adoption.

- Vendor Reputation and Support: Research the vendor’s track record, customer reviews, and the quality of their technical support and training resources.

- Deployment Model: Decide between cloud-based (SaaS) and on-premise solutions. Cloud offers flexibility, lower upfront costs, and automatic updates, while on-premise provides more control over data and customization.

- Cost vs. ROI: Evaluate the total cost of ownership (subscriptions, implementation, training) against the projected return on investment (cost savings, increased sales).

Implementation Best Practices

A successful IMS implementation goes beyond simply purchasing the software:

- Thorough Planning: Define clear objectives, map out existing processes, and identify areas for improvement.

- Data Migration: Accurately transfer all existing inventory data into the new system. This often involves significant data cleansing.

- Staff Training: Provide comprehensive training for all users to ensure they understand the software’s functionalities and how to integrate it into their daily tasks.

- Phased Rollout: Consider a phased implementation, starting with a smaller module or location, to identify and resolve issues before a full-scale deployment.

- Continuous Improvement: Regularly review performance metrics, gather user feedback, and make adjustments to optimize processes and leverage new features.

The Future of Inventory Management Software

The landscape of inventory management is continuously evolving, driven by technological advancements:

- Artificial Intelligence (AI) and Machine Learning (ML): These technologies will enhance forecasting accuracy, predict demand fluctuations with greater precision, and optimize pricing strategies.

- Internet of Things (IoT): Sensors on shelves, pallets, and products will provide real-time data on temperature, humidity, movement, and even potential damage, further automating inventory tracking.

- Blockchain Technology: Offers enhanced transparency and traceability across the entire supply chain, especially valuable for verifying product authenticity and origin.

- Mobile Accessibility: Increasing reliance on mobile apps for on-the-go inventory management, allowing warehouse staff and field agents to update data from anywhere.

- Robotics and Automation: Integration with automated guided vehicles (AGVs) and robotic picking systems will further streamline warehouse operations.

Conclusion

In an era defined by rapid change and intense competition, effective inventory management is no longer a luxury but a fundamental necessity. Business Inventory Management Software transforms a complex, error-prone process into a streamlined, data-driven operation. By providing real-time visibility, automating key functions, and delivering actionable insights, IMS empowers businesses to reduce costs, enhance efficiency, improve customer satisfaction, and build a resilient foundation for sustainable growth. For any organization looking to thrive in the modern marketplace, investing in the right inventory management software is not just an operational upgrade—it’s a strategic investment in the future.