Mastering Your Stock: The Indispensable Role of Business Inventory Programs

In the fast-paced world of commerce, inventory is more than just a collection of goods; it represents a significant portion of a business’s assets, a critical link in the supply chain, and a direct determinant of customer satisfaction and profitability. Mismanaged inventory can lead to a myriad of problems: lost sales due to stockouts, wasted capital on obsolete or excess stock, operational inefficiencies, and inaccurate financial reporting. This is where the business inventory program steps in, transforming what was once a cumbersome, error-prone manual process into a streamlined, data-driven engine for growth.

What is a Business Inventory Program?

At its core, a business inventory program is a software solution designed to track, manage, and optimize a company’s stock from the moment it enters the warehouse to the point it’s sold or consumed. It provides a centralized system for businesses to monitor their goods, whether they are raw materials, work-in-progress, or finished products. Far beyond simple counting, these programs offer a comprehensive suite of tools that facilitate everything from purchase order management and sales order fulfillment to warehouse organization, demand forecasting, and detailed reporting.

For businesses of all sizes, from a small e-commerce startup to a multinational manufacturing giant, an inventory program acts as the central nervous system for their physical assets, providing real-time visibility and control over one of their most valuable and dynamic resources.

The Critical Need: Why Inventory Management Matters

The importance of robust inventory management cannot be overstated. It directly impacts a company’s financial health, operational efficiency, and ability to meet customer expectations.

- Financial Health: Inventory ties up significant capital. Overstocking leads to increased carrying costs (storage, insurance, obsolescence, spoilage), while understocking results in lost sales opportunities and potential customer dissatisfaction. An effective inventory program helps strike the delicate balance, minimizing capital expenditure while maximizing sales potential.

- Operational Efficiency: Manual inventory processes are notoriously inefficient and prone to human error. Locating items, processing orders, and conducting stock counts can consume vast amounts of time and labor. Automated systems streamline these tasks, freeing up resources and improving overall productivity.

- Customer Satisfaction: In today’s competitive market, customers expect products to be available when they want them. Stockouts lead to frustrated customers who will likely take their business elsewhere. Conversely, quick and accurate order fulfillment, enabled by precise inventory data, enhances the customer experience and builds brand loyalty.

- Strategic Decision-Making: Without accurate data, strategic decisions regarding purchasing, pricing, and marketing are mere guesswork. An inventory program provides the data necessary for informed decision-making, allowing businesses to adapt quickly to market changes and capitalize on new opportunities.

Unlocking Value: Key Benefits of Implementing an Inventory Program

The adoption of a dedicated inventory management solution yields a multitude of tangible and intangible benefits that directly contribute to a business’s bottom line and competitive edge.

-

Enhanced Accuracy and Real-time Visibility:

Perhaps the most immediate benefit, inventory programs eliminate the guesswork associated with manual tracking. Using barcode scanning, RFID, or other automated data capture methods, businesses gain precise, real-time insights into stock levels, locations, and movement. This accuracy drastically reduces errors, discrepancies, and the need for time-consuming physical counts, ensuring that the reported stock matches the actual stock on hand. -

Optimized Stock Levels:

One of the core objectives of inventory management is to maintain optimal stock levels – enough to meet demand without incurring excessive carrying costs. Inventory programs leverage historical sales data, seasonal trends, and demand forecasting tools to predict future needs. This capability helps businesses prevent costly overstocking (which ties up capital and risks obsolescence) and frustrating understocking (which leads to lost sales and customer dissatisfaction). -

Reduced Costs:

The financial benefits are substantial. By optimizing stock levels, businesses can significantly reduce carrying costs associated with storage, insurance, security, and depreciation. Reduced errors mean less need for costly rework or expedited shipping. Furthermore, minimizing obsolescence and spoilage, particularly for perishable goods, directly translates into fewer write-offs and improved profitability. -

Improved Efficiency and Productivity:

Automation is a game-changer. Inventory programs automate routine tasks such as stock counting, reordering, and data entry. This frees up staff to focus on more strategic activities, increasing overall productivity. Streamlined workflows for receiving, picking, packing, and shipping accelerate order fulfillment, leading to faster delivery times and a more agile operation. -

Better Decision-Making Through Data Analytics:

Inventory programs are powerful data repositories. They collect vast amounts of information on sales trends, product performance, supplier reliability, and stock movement. Advanced reporting and analytics features transform this raw data into actionable insights. Businesses can identify top-selling products, slow-moving items, seasonal fluctuations, and supplier performance issues, enabling data-driven decisions for purchasing, pricing, marketing, and product development. -

Enhanced Customer Satisfaction:

With accurate inventory data, businesses can confidently promise delivery times and fulfill orders reliably. Fewer stockouts mean fewer disappointed customers and a stronger reputation. Efficient order processing leads to faster delivery, further enhancing the customer experience and fostering loyalty. -

Streamlined Supply Chain Management:

Inventory programs often integrate with other supply chain components, such as supplier management and logistics. This integration provides end-to-end visibility, allowing businesses to monitor supplier performance, track shipments, and manage returns more effectively, creating a more robust and responsive supply chain. -

Compliance and Auditing:

For many industries, accurate inventory records are crucial for regulatory compliance and financial auditing. Inventory programs maintain a detailed audit trail of all stock movements, making it easier to demonstrate compliance, reconcile financial statements, and prepare for audits with confidence.

Essential Features to Look For in an Inventory Program

When selecting an inventory program, businesses should consider a range of features that cater to their specific needs and operational complexities:

- Real-time Tracking: The ability to see stock levels and locations instantly. This often involves integration with barcode scanners, RFID readers, or other data capture devices.

- Multi-location/Warehouse Management: Essential for businesses with multiple storage facilities, enabling tracking of stock across all locations.

- Purchase Order (PO) Management: Tools to create, send, and track purchase orders, linking incoming stock directly to inventory.

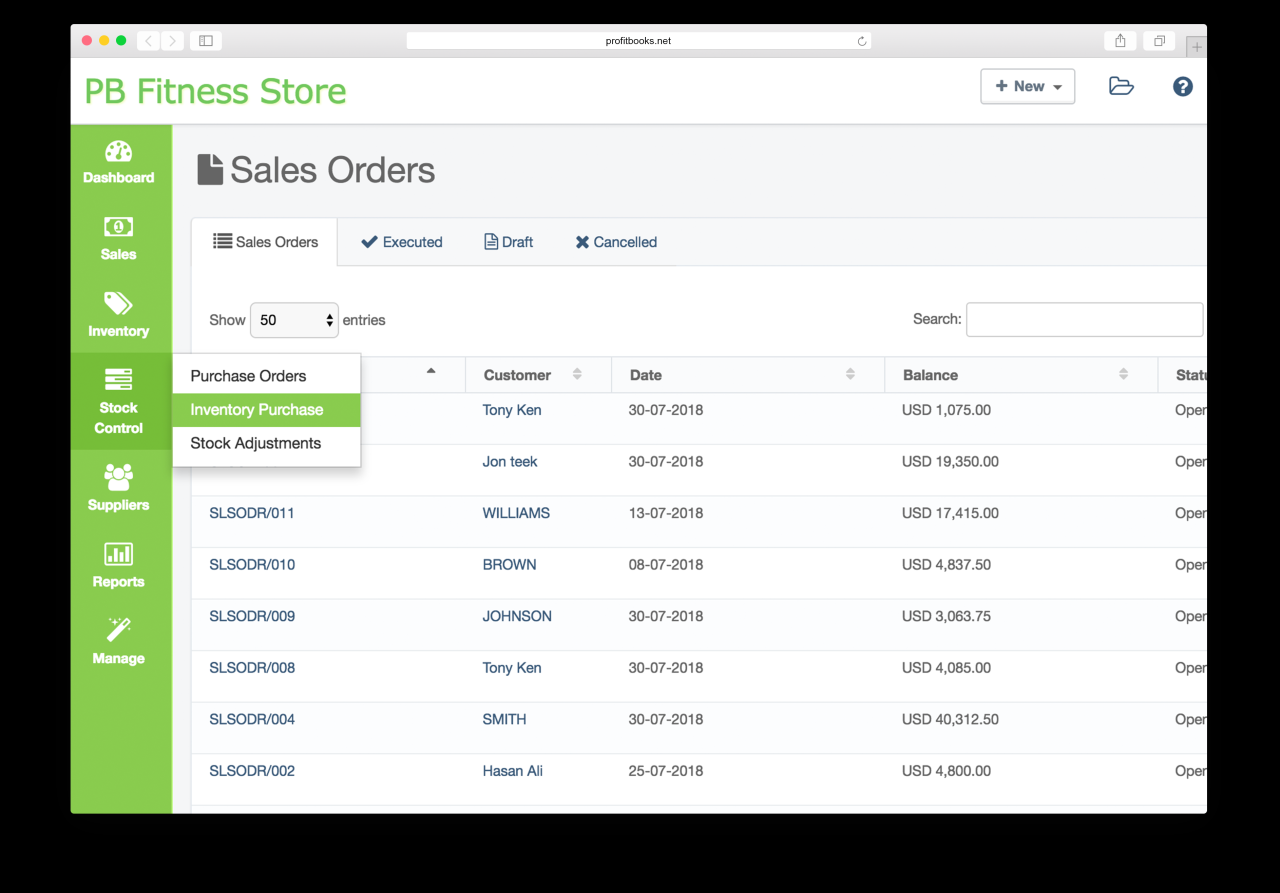

- Sales Order Management: Integration with sales channels (e-commerce, POS) to deduct sold items from inventory automatically and manage order fulfillment.

- Reporting and Analytics: Comprehensive dashboards and customizable reports on stock levels, sales trends, slow-moving items, carrying costs, and supplier performance.

- Demand Forecasting: Algorithms that use historical data to predict future demand, aiding in optimal reorder points and quantities.

- Lot/Serial Number Tracking: Crucial for industries requiring detailed tracking of specific items, such as food and beverage (batch numbers), electronics (serial numbers), or pharmaceuticals (expiry dates).

- Inventory Optimization Tools: Features like ABC analysis, minimum/maximum stock levels, and safety stock calculations to fine-tune inventory holdings.

- Integration Capabilities: The ability to seamlessly connect with other business systems, such as accounting software (e.g., QuickBooks, Xero), ERP systems, e-commerce platforms (e.g., Shopify, Magento), and shipping carriers.

- User-Friendly Interface: An intuitive design that minimizes the learning curve and encourages user adoption.

- Mobile Access: The ability to manage inventory on the go via smartphones or tablets, especially useful for warehouse staff or field sales teams.

- Security and Backup: Robust data security measures and reliable backup options to protect critical inventory information.

Implementing Your Inventory Program: A Strategic Approach

Implementing an inventory program is not merely about installing software; it’s a strategic project that requires careful planning and execution.

- Define Your Needs and Goals: Clearly identify the pain points you want to address and the specific objectives you aim to achieve (e.g., reduce stockouts by 20%, improve picking efficiency by 15%).

- Data Clean-up and Migration: Accurate inventory data is paramount. Invest time in cleaning up existing data, standardizing product descriptions, and ensuring data integrity before migrating it to the new system.

- Process Mapping and Redesign: Review your current inventory processes and identify areas for improvement that the new system can facilitate. Be prepared to adapt your workflows to leverage the program’s capabilities fully.

- Staff Training: User adoption is crucial. Provide comprehensive training to all staff who will interact with the system, from warehouse personnel to sales and finance teams. Emphasize the benefits and how the system simplifies their tasks.

- Phased Rollout: Consider a phased implementation, starting with a smaller section of your inventory or a specific warehouse, before rolling it out company-wide. This allows for testing, adjustments, and minimizes disruption.

- Ongoing Optimization and Review: An inventory program is not a "set it and forget it" solution. Regularly review its performance, analyze reports, and make adjustments to settings and processes to continually optimize your inventory management.

The Future of Inventory Management

The landscape of inventory management is continuously evolving, driven by technological advancements. Emerging trends are set to make inventory programs even more intelligent, autonomous, and integrated:

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms are enhancing demand forecasting capabilities, identifying complex patterns in sales data, predicting potential supply chain disruptions, and optimizing pricing strategies.

- Internet of Things (IoT): IoT devices, such as smart shelves with weight sensors or RFID tags, can provide real-time, granular data on inventory levels and movement, automating reordering processes and reducing human intervention.

- Robotics and Automation: Automated guided vehicles (AGVs) and robotic picking systems in warehouses are integrating with inventory programs to manage stock movement and fulfillment with unprecedented speed and accuracy.

- Blockchain Technology: Blockchain offers the potential for enhanced transparency and traceability across the entire supply chain, providing an immutable record of product origin, movement, and authenticity.

- Cloud-based Solutions: The shift towards cloud-based inventory programs continues, offering scalability, accessibility from anywhere, automatic updates, and reduced IT infrastructure costs.

Conclusion

In today’s competitive business environment, effective inventory management is no longer a luxury but a fundamental necessity. A robust business inventory program is an indispensable tool that empowers companies to gain unparalleled visibility and control over their stock. By automating processes, enhancing accuracy, optimizing stock levels, and providing actionable insights, these programs significantly reduce costs, improve operational efficiency, and elevate customer satisfaction.

Investing in the right inventory program is a strategic decision that pays dividends in profitability, resilience, and sustainable growth. As technology continues to advance, the capabilities of these programs will only expand, further cementing their role as the backbone of successful modern businesses. For any enterprise looking to thrive in an increasingly complex marketplace, mastering your stock with a comprehensive inventory solution is the clearest path forward.