Mastering the Flow: A Comprehensive Guide to Business Inventory Strategy

In the intricate dance of modern commerce, inventory acts as the lifeblood of a business. It represents a significant investment, directly impacting cash flow, operational efficiency, and ultimately, customer satisfaction. Yet, managing this critical asset is a delicate balancing act. Too much inventory can tie up capital, incur excessive carrying costs, and risk obsolescence. Too little, and a business faces stockouts, lost sales, production delays, and a tarnished reputation. This inherent tension underscores the paramount importance of a well-defined and dynamic Business Inventory Strategy.

This article will delve into the multifaceted world of inventory strategy, exploring its core principles, various models, implementation steps, and future trends, aiming to equip businesses with the knowledge to optimize their inventory flow for sustainable growth and competitive advantage.

I. The Core Purpose: Balancing Act of Cost and Service

At its heart, inventory strategy is about finding the optimal equilibrium between two opposing forces:

- Minimizing Costs: This includes purchasing costs, ordering costs, carrying costs (storage, insurance, obsolescence, damage, theft), and shortage costs (expedited shipping, lost production).

- Maximizing Customer Service Level: Ensuring products are available when customers want them, fulfilling orders promptly, and maintaining consistent production schedules.

A robust inventory strategy aims to achieve these objectives by:

- Reducing Capital Tied Up: Freeing up cash for other investments.

- Improving Operational Efficiency: Streamlining processes from procurement to dispatch.

- Mitigating Risks: Protecting against demand fluctuations, supply disruptions, and product obsolescence.

- Enhancing Customer Satisfaction: Ensuring product availability and reliable delivery.

II. Key Principles and Pillars of Effective Inventory Strategy

Building a successful inventory strategy isn’t a one-size-fits-all endeavor. It rests upon several foundational principles:

-

Accurate Demand Forecasting: This is arguably the most critical pillar. Without a reliable prediction of future demand, all other inventory decisions are guesswork. Forecasting utilizes historical sales data, market trends, seasonality, promotional impacts, and even external factors like economic indicators or social media sentiment. The goal is not perfection, but continuous improvement in accuracy.

-

Supply Chain Visibility and Collaboration: An effective strategy requires end-to-end visibility across the supply chain – from raw material suppliers to the end customer. Collaboration with suppliers (for lead times, quality, reliability) and distributors (for market insights) is crucial to preempting issues and optimizing flow.

-

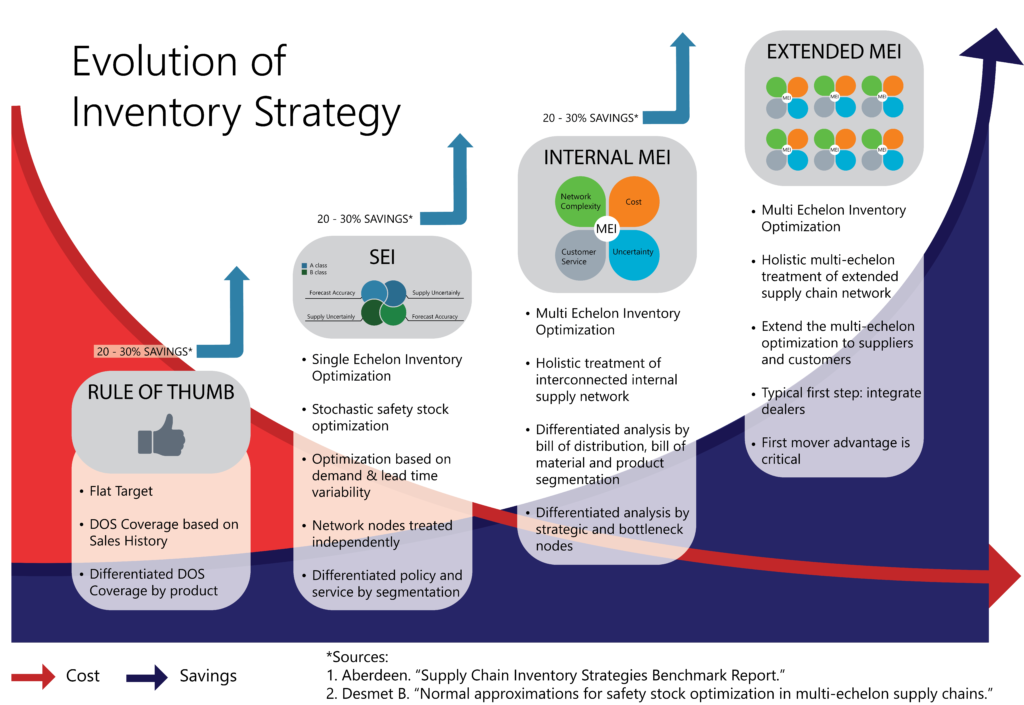

Cost Analysis and Optimization: Businesses must thoroughly understand all costs associated with inventory. This includes:

- Ordering Costs: Costs incurred each time an order is placed (e.g., administrative, shipping).

- Carrying Costs: The cost of holding inventory over time (e.g., warehousing, insurance, spoilage, opportunity cost of capital).

- Stockout Costs: The most insidious, including lost sales, expedited shipping, production stoppages, and damage to brand reputation.

-

Technology Adoption: Modern inventory management is virtually impossible without technology. Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), and advanced analytics tools provide real-time data, automate processes, and offer predictive insights, transforming inventory from a static asset into a dynamic, data-driven resource.

-

Continuous Improvement and Adaptability: The business landscape is constantly evolving. An inventory strategy must not be static but agile and adaptable. Regular reviews, performance monitoring (using Key Performance Indicators like inventory turnover, fill rate, stockout rate), and a willingness to adjust based on new data or market conditions are essential.

III. Popular Inventory Management Strategies and Models

Various strategies and models have been developed to tackle different inventory challenges. Businesses often employ a combination of these:

-

Just-In-Time (JIT) Inventory:

- Concept: Pioneered by Toyota, JIT aims to minimize inventory levels by receiving goods only as they are needed for production or sale. It’s a "pull" system driven by actual demand.

- Pros: Dramatically reduces carrying costs, waste, and obsolescence; improves cash flow; enhances quality by exposing issues quickly.

- Cons: Highly vulnerable to supply chain disruptions; requires impeccable forecasting and reliable suppliers; can lead to stockouts if demand surges unexpectedly.

- Best for: Businesses with stable demand, strong supplier relationships, and high-value, fast-moving items.

-

Economic Order Quantity (EOQ):

- Concept: A mathematical formula that calculates the optimal order quantity to minimize the total inventory costs (ordering costs + carrying costs) over a period.

- Formula: $EOQ = sqrt((2DS)/H)$ where D = annual demand, S = ordering cost per order, H = carrying cost per unit per year.

- Pros: Provides a clear, data-driven order quantity; helps balance ordering and carrying costs.

- Cons: Assumes constant demand, known costs, and instant replenishment, which are rarely true in dynamic environments; doesn’t account for bulk discounts or supply chain volatility.

- Best for: Independent demand items with relatively stable usage and costs.

-

Materials Requirements Planning (MRP / MRP II):

- Concept: A planning and scheduling system used to manage inventory for dependent demand items (components needed for a final product). MRP calculates what materials are needed, when, and in what quantities, based on a master production schedule and bill of materials (BOM). MRP II expands this to include financial and operational planning.

- Pros: Ensures materials are available for production; optimizes procurement schedules; reduces work-in-progress (WIP) inventory.

- Cons: Requires accurate BOMs and production schedules; complex to implement and manage; less flexible for sudden changes.

- Best for: Manufacturing environments with complex products and multiple stages of production.

-

ABC Analysis:

- Concept: A categorization technique that ranks inventory items by their value or contribution to profit.

- A-items: High-value, low-volume (e.g., 20% of items, 80% of value). Require strict control, frequent review, and accurate forecasting.

- B-items: Medium-value, medium-volume (e.g., 30% of items, 15% of value). Moderate control.

- C-items: Low-value, high-volume (e.g., 50% of items, 5% of value). Simpler control, often ordered in larger quantities to reduce ordering costs.

- Pros: Focuses management effort where it matters most; optimizes control levels for different items.

- Cons: Requires regular re-evaluation of categories; can be subjective in defining value.

- Best for: Businesses with a wide range of products with varying importance.

- Concept: A categorization technique that ranks inventory items by their value or contribution to profit.

-

Safety Stock:

- Concept: Extra inventory held to guard against uncertainties in demand or supply lead times. It acts as a buffer to prevent stockouts during unexpected fluctuations.

- Calculation: Often determined using statistical methods based on demand variability and desired service level.

- Pros: Improves customer service by preventing stockouts; provides a cushion against unforeseen events.

- Cons: Increases carrying costs; requires careful calculation to avoid excessive stock.

- Best for: All businesses to manage inherent variability, especially for critical items.

-

Vendor-Managed Inventory (VMI):

- Concept: The supplier takes responsibility for managing and replenishing the customer’s inventory levels. The supplier monitors the customer’s stock and initiates orders as needed.

- Pros: Reduces administrative burden for the customer; improves supply chain efficiency and collaboration; often leads to better forecasting for the supplier.

- Cons: Requires a high degree of trust and data sharing; customer loses some direct control over inventory.

- Best for: Strong, long-term supplier-customer relationships, particularly for frequently purchased items.

IV. Developing and Implementing Your Inventory Strategy

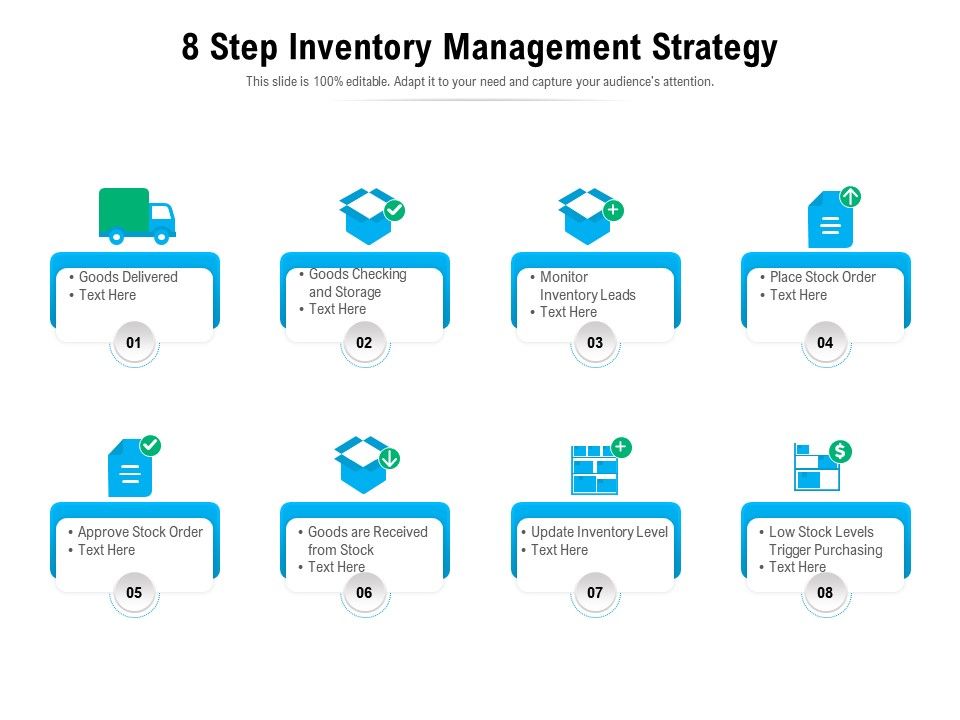

Building an effective inventory strategy involves a structured approach:

- Assess Your Current State: Conduct a thorough audit of existing inventory levels, processes, costs, and historical performance (turnover, stockout rates). Identify pain points and inefficiencies.

- Define Clear Objectives: What are you trying to achieve? (e.g., "Reduce carrying costs by 15%," "Improve order fulfillment rate to 98%," "Decrease stockouts by 50%"). Ensure objectives are SMART (Specific, Measurable, Achievable, Relevant, Time-bound).

- Choose Appropriate Models and Techniques: Based on your products (A, B, C categories), demand patterns, industry, and strategic objectives, select the most suitable inventory management models (e.g., JIT for fast-moving items, MRP for manufacturing components, EOQ for stable independent items).

- Leverage Technology: Invest in or upgrade to robust ERP and WMS systems. Explore advanced analytics, AI, and machine learning tools for enhanced forecasting and optimization.

- Foster Collaboration and Training: Ensure all relevant departments (purchasing, sales, production, warehousing) are aligned and understand the strategy. Train staff on new systems and processes.

- Monitor, Analyze, and Adapt: Implement key performance indicators (KPIs) and regularly review performance against objectives. Be prepared to adjust your strategy based on market changes, supply chain disruptions, or new data. This iterative process is crucial for long-term success.

V. Challenges and Future Trends

The landscape of inventory management is constantly evolving. Businesses face new challenges and opportunities:

- Global Supply Chain Volatility: Events like pandemics, geopolitical tensions, and natural disasters highlight the need for resilience, diversification of suppliers, and robust risk management in inventory planning.

- E-commerce Acceleration: The rapid growth of online retail demands faster fulfillment, distributed inventory, and sophisticated last-mile delivery strategies.

- Sustainability and Ethics: Consumers and regulators increasingly demand sustainable practices. Inventory strategies must consider ethical sourcing, waste reduction, and reverse logistics.

- Artificial Intelligence and Machine Learning: AI/ML are revolutionizing forecasting accuracy, enabling predictive analytics for demand and supply, and optimizing warehouse operations.

- Blockchain Technology: Offers potential for unprecedented transparency and traceability throughout the supply chain, enhancing trust and efficiency.

- Omnichannel Fulfillment: Managing inventory across multiple sales channels (online, in-store, mobile) requires integrated systems and dynamic allocation strategies.

Conclusion

A well-crafted Business Inventory Strategy is not merely a tactical exercise; it is a fundamental pillar of operational excellence and competitive advantage. By understanding the delicate balance between cost and service, embracing data-driven principles, selectively applying proven models, and leveraging cutting-edge technology, businesses can transform their inventory from a potential liability into a strategic asset. In a world of increasing complexity and volatility, mastering the flow of goods is no longer an option but a necessity for sustainable success. The journey is continuous, requiring constant vigilance, adaptation, and a commitment to perpetual improvement.