Mastering the Flow: A Comprehensive Guide to Business Inventory Management

In the intricate dance of supply and demand, inventory stands as the silent, yet most critical, asset for many businesses. From manufacturing plants to retail storefronts, the goods a company holds are not just products; they represent capital, potential sales, and the very promise made to customers. Effective Business Inventory Management is the art and science of ensuring these assets are optimally acquired, stored, and utilized. It’s a strategic imperative that directly impacts a company’s financial health, operational efficiency, and customer satisfaction.

This article delves into the core principles, methodologies, technological advancements, and best practices that underpin successful inventory management, aiming to provide a comprehensive understanding for businesses striving for excellence in their supply chain.

The Essence of Inventory Management: More Than Just Counting

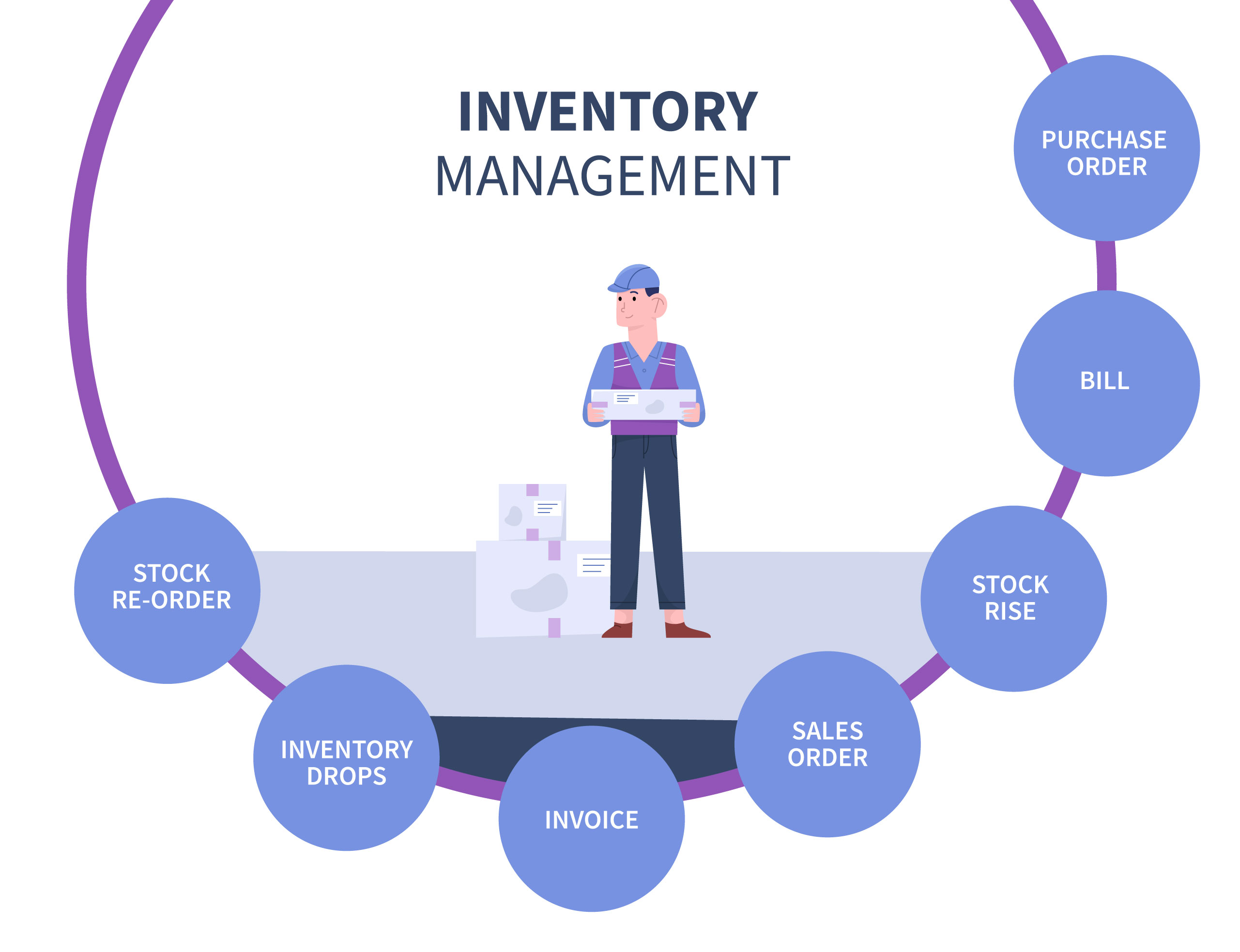

At its heart, inventory management is the systematic process of overseeing and controlling the ordering, storage, and use of a company’s inventory. This includes raw materials, components, work-in-progress (WIP), and finished goods, as well as maintenance, repair, and operating (MRO) supplies. The ultimate goal is to strike a delicate balance: having enough stock to meet customer demand without holding excessive inventory that ties up capital, incurs storage costs, and risks obsolescence.

Why is it indispensable?

- Optimizing Cash Flow: Inventory is capital. Excess inventory means capital is locked up, unable to be invested elsewhere. Efficient management frees up cash.

- Meeting Customer Demand: Accurate inventory ensures products are available when customers want them, preventing stockouts and lost sales, and fostering customer loyalty.

- Reducing Costs: Minimizing holding costs (storage, insurance, spoilage, obsolescence) and preventing expedited shipping fees due to last-minute shortages.

- Improving Operational Efficiency: Streamlining production schedules, reducing bottlenecks, and enhancing the overall flow of goods through the supply chain.

- Gaining Competitive Advantage: Businesses with superior inventory management can offer better service, more competitive pricing, and faster fulfillment.

Types of Inventory: Understanding Your Assets

To manage inventory effectively, it’s crucial to understand the different forms it takes within a business:

- Raw Materials: Basic inputs used in the production process (e.g., wood for furniture, fabric for clothing, silicon for electronics).

- Work-in-Progress (WIP): Partially finished goods that are still undergoing production or assembly.

- Finished Goods: Products that are complete and ready for sale to customers.

- Maintenance, Repair, and Operations (MRO) Inventory: Items used to support the production process and general operations, but not directly incorporated into the final product (e.g., spare parts, cleaning supplies, office stationery).

- Transit Inventory: Goods being transported between locations.

- Buffer/Safety Stock: Extra inventory held to mitigate risks of stockouts due to unexpected demand spikes or supply chain disruptions.

Each type requires a tailored approach to management, considering its cost, lead time, and criticality to the business.

Common Challenges in Inventory Management

Despite its importance, inventory management is fraught with challenges:

- Stockouts (Understocking): Running out of popular items leads to lost sales, dissatisfied customers, and potentially damaged brand reputation.

- Overstocking: Holding too much inventory incurs high carrying costs (storage, insurance, security), risks obsolescence or spoilage, and ties up valuable working capital.

- Inaccurate Inventory Records: Discrepancies between physical stock and system records lead to poor decision-making, operational disruptions, and inefficiencies.

- Seasonality and Demand Variability: Fluctuations in demand due to seasons, trends, or promotions make accurate forecasting difficult.

- Supply Chain Disruptions: Unexpected events like natural disasters, geopolitical issues, or supplier failures can severely impact inventory levels and lead times.

- Obsolete Inventory: Products that become outdated, damaged, or unsellable, resulting in write-offs and financial losses.

Core Strategies and Methodologies for Effective Management

Addressing these challenges requires a strategic blend of methodologies and tools:

- Demand Forecasting: This is the bedrock of effective inventory management. Using historical sales data, market trends, economic indicators, and even predictive analytics, businesses can anticipate future demand more accurately. Both quantitative (time series, regression) and qualitative (expert opinion, market research) methods are employed.

- Inventory Control Models:

- Economic Order Quantity (EOQ): A formula that calculates the optimal order quantity to minimize the total cost of ordering and holding inventory. It balances the cost of placing an order with the cost of holding inventory.

- Reorder Point (ROP): The specific inventory level at which a new order should be placed to replenish stock. It considers lead time demand and safety stock.

- Safety Stock: An additional quantity of an item held in inventory to reduce the risk of a stockout. It acts as a buffer against unforeseen fluctuations in demand or supply lead times.

- Inventory Classification:

- ABC Analysis: Categorizes inventory items based on their value or importance.

- A-items: High-value, low-volume items (e.g., critical components). Managed tightly with frequent reviews.

- B-items: Medium-value, medium-volume items. Managed with moderate control.

- C-items: Low-value, high-volume items (e.g., office supplies). Managed with simpler controls.

This method allows businesses to allocate resources and attention where they are most impactful.

- ABC Analysis: Categorizes inventory items based on their value or importance.

- Just-in-Time (JIT) Inventory: A lean inventory strategy where materials and goods are received only as they are needed in the production process, minimizing holding costs and waste. It requires highly reliable suppliers and precise forecasting.

- First-In, First-Out (FIFO) / Last-In, First-Out (LIFO): These are accounting methods for valuing inventory. While not directly managing physical flow, they impact financial reporting and tax implications, which in turn influence inventory decisions. FIFO is often preferred for perishable goods to ensure older stock is sold first.

The Role of Technology in Modern Inventory Management

The complexity and scale of modern businesses make manual inventory management virtually impossible. Technology has become an indispensable ally:

- Inventory Management Systems (IMS) / Warehouse Management Systems (WMS): These software solutions provide real-time visibility into inventory levels across multiple locations. They automate tasks like order processing, stock tracking, receiving, picking, packing, and shipping, significantly reducing errors and improving efficiency.

- Enterprise Resource Planning (ERP) Systems: ERPs integrate inventory management with other critical business functions such as sales, purchasing, finance, and production. This holistic view ensures consistent data and coordinated decision-making across the organization.

- Barcode and RFID Technology: These technologies enable rapid and accurate tracking of items from receipt to dispatch. Barcodes are cost-effective, while RFID (Radio-Frequency Identification) offers faster, hands-free scanning and greater data capacity, ideal for high-volume environments.

- Demand Forecasting Software: Advanced algorithms, machine learning, and AI capabilities within these systems can analyze vast datasets to generate highly accurate demand predictions, even for volatile products.

- E-commerce Integration: For businesses operating online, integrating inventory systems with e-commerce platforms ensures that online stock levels are always accurate, preventing overselling or disappointing customers.

Best Practices for Effective Inventory Management

Beyond specific tools and strategies, certain best practices underpin robust inventory management:

- Regular Audits and Cycle Counting: Instead of disruptive annual physical counts, cycle counting involves counting a small portion of inventory on a regular basis. This helps identify discrepancies early and improves accuracy.

- Strong Supplier Relationship Management: Collaborating closely with suppliers ensures reliable lead times, quality control, and potential for volume discounts or flexible delivery schedules.

- Employee Training: Well-trained staff who understand the importance of accurate data entry, proper handling, and adherence to procedures are crucial.

- Data Analytics and Reporting: Regularly analyzing inventory data (e.g., turnover rates, carrying costs, stockout rates) provides actionable insights for continuous improvement.

- Contingency Planning: Developing strategies for unexpected events (e.g., backup suppliers, emergency stock, alternative shipping routes) can mitigate disruptions.

- Continuous Improvement: Inventory management is not a one-time fix but an ongoing process of optimization, adapting to market changes and technological advancements.

Future Trends in Inventory Management

The landscape of inventory management is continuously evolving, driven by technological innovation and shifting market demands:

- Artificial Intelligence (AI) and Machine Learning (ML): AI will further enhance predictive analytics for demand forecasting, optimize pricing strategies, and even automate order placement. ML algorithms can identify patterns invisible to human analysts, leading to more precise inventory adjustments.

- Internet of Things (IoT): Smart shelves, sensors, and connected devices will provide real-time location and condition monitoring of inventory, minimizing losses due to damage or theft and enabling more dynamic stock adjustments.

- Blockchain Technology: Offering immutable and transparent records, blockchain can enhance supply chain traceability, verify product authenticity, and streamline cross-organizational inventory reconciliation.

- Sustainability and Circular Economy: Growing emphasis on environmental responsibility will push inventory management towards reducing waste, optimizing reverse logistics for returns and recycling, and sourcing ethically.

- Hyper-personalization: As customer expectations for customized products grow, inventory systems will need to support more agile, on-demand manufacturing and distribution models, potentially involving micro-warehouses and advanced robotics.

Conclusion

Business inventory management is far more than a logistical challenge; it is a strategic pillar for sustained growth and profitability. In an increasingly competitive and volatile global marketplace, the ability to efficiently manage inventory directly translates into operational resilience, enhanced customer satisfaction, and a robust bottom line. By embracing a combination of proven methodologies, leveraging cutting-edge technology, and fostering a culture of continuous improvement, businesses can master the flow of their inventory, transforming it from a potential liability into a powerful engine for success. It is an ongoing journey of optimization, but one that is absolutely essential for any enterprise aiming to thrive in the modern economic landscape.