Mastering the Art of Business Inventory Ordering: A Strategic Imperative for Success

In the intricate dance of modern commerce, inventory stands as both a vital asset and a potential liability. For businesses across every sector, from retail to manufacturing, the efficient management of inventory is not merely a logistical task but a strategic imperative that directly impacts profitability, customer satisfaction, and operational resilience. At the heart of this management lies the process of inventory ordering – a seemingly simple act of replenishment that, when executed with precision and foresight, can be a powerful differentiator.

This article delves deep into the multifaceted world of business inventory ordering, exploring its critical role, the myriad factors influencing decision-making, various methodologies, the transformative power of technology, and best practices for achieving optimal results. Our aim is to illuminate how mastering this art can transform a business from merely surviving to truly thriving in today’s competitive landscape.

The Crucial Role of Inventory Ordering

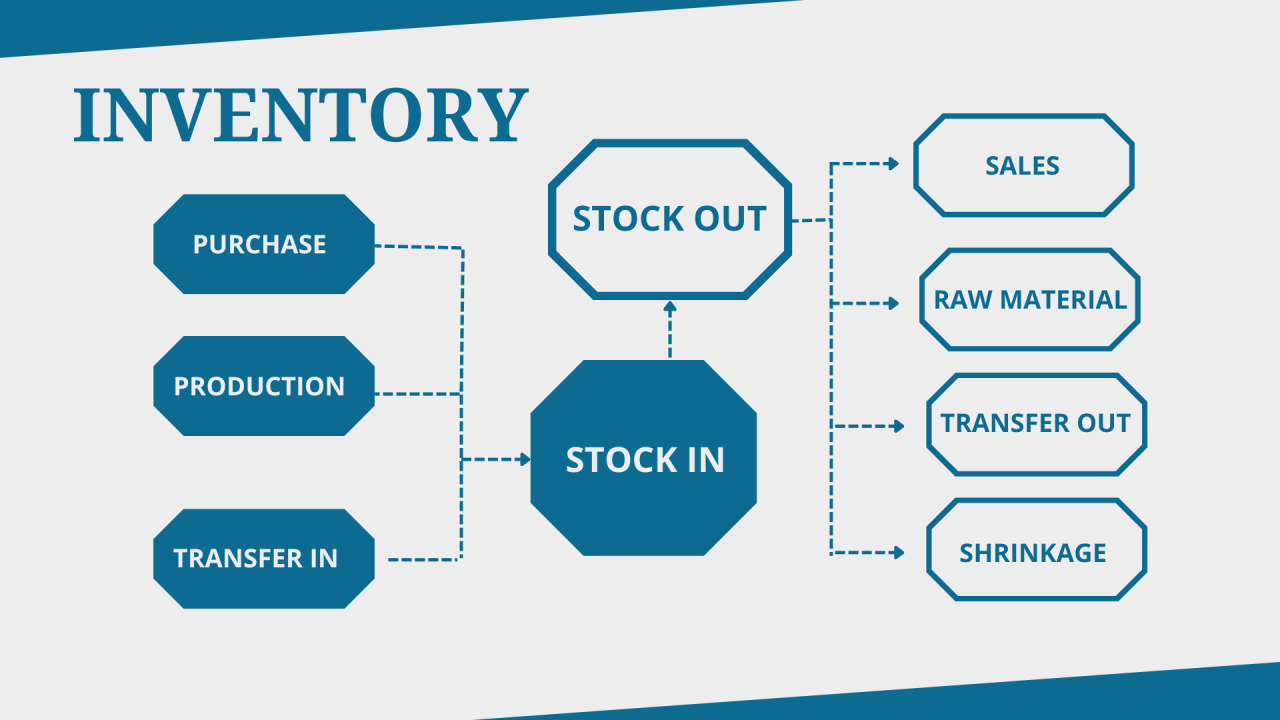

Inventory, broadly defined, encompasses all the goods and materials a business holds for sale or for use in the production of goods to be sold. The act of ordering these items dictates the availability of products, the efficiency of production lines, and ultimately, the financial health of the organization. Poor inventory ordering can lead to two equally detrimental scenarios:

- Stockouts (Understocking): Running out of popular items means lost sales, frustrated customers, damaged reputation, and potential loss of market share to competitors who do have the product. In manufacturing, stockouts of raw materials can halt production, leading to expensive downtime and missed deadlines.

- Overstocking: Holding excessive inventory ties up valuable capital that could be used elsewhere. It incurs significant carrying costs (storage, insurance, security, obsolescence, spoilage), increases the risk of product devaluation or expiry, and can lead to markdowns that erode profit margins.

Effective inventory ordering, therefore, is a delicate balancing act. It seeks to ensure that the right products are available at the right time, in the right quantities, and at the lowest possible cost, thereby maximizing customer satisfaction while minimizing financial waste.

Key Objectives of Effective Inventory Ordering

Beyond simply having enough stock, strategic inventory ordering aims to achieve several critical objectives:

- Cost Minimization: This is perhaps the most direct objective, encompassing the reduction of carrying costs, ordering costs (administrative expenses, shipping), and stockout costs.

- Customer Satisfaction Maximization: Ensuring product availability is paramount for meeting customer expectations and fostering loyalty.

- Operational Efficiency: Smooth inventory flow prevents bottlenecks in production and sales, leading to more streamlined operations.

- Cash Flow Optimization: By avoiding overstocking, businesses free up capital, improving liquidity and financial flexibility.

- Waste Reduction: Minimizing obsolescence, spoilage, and returns contributes to sustainability and cost savings.

Factors Influencing Inventory Ordering Decisions

The decision of what, when, and how much to order is influenced by a complex interplay of internal and external factors:

- Demand Variability: The most significant factor. Demand can be stable, seasonal, trending, or highly unpredictable. Accurate demand forecasting is crucial here, utilizing historical data, market trends, promotional plans, and even external economic indicators.

- Lead Time: The duration between placing an order and receiving the goods. Longer lead times necessitate earlier ordering and potentially larger safety stocks. Supplier reliability plays a huge role here.

- Carrying Costs (Holding Costs): The expenses associated with storing inventory. This includes warehouse rent, utilities, insurance, security, labor for handling, obsolescence risk, and the opportunity cost of capital tied up in inventory.

- Ordering Costs: The administrative and logistical expenses incurred each time an order is placed. This includes the cost of processing paperwork, communicating with suppliers, receiving and inspecting goods, and transportation.

- Stockout Costs: The intangible and tangible costs of running out of stock, including lost sales, expedited shipping fees, customer dissatisfaction, and damage to brand reputation.

- Obsolescence and Perishability: Products with short shelf lives or those prone to rapid technological change require extremely careful ordering to avoid losses.

- Supplier Reliability and Relationships: A dependable supplier with consistent lead times and quality products simplifies ordering. Strong supplier relationships can also lead to better pricing and more flexible terms.

- Economic Order Quantity (EOQ): A classic inventory management formula that calculates the optimal order quantity to minimize the total of carrying costs and ordering costs. While a theoretical model, it provides a valuable baseline.

- Storage Capacity: Physical limitations of warehouse space can dictate order sizes, especially for bulky items.

Common Inventory Ordering Models and Strategies

Businesses employ various models and strategies to manage their inventory ordering, each suited to different contexts and product types:

-

Reorder Point (ROP) System (Continuous Review):

- How it works: Inventory levels are continuously monitored. When the stock of an item drops to a predetermined reorder point, a fixed quantity (often the EOQ) is ordered.

- Best for: High-value, critical, or fast-moving items where stockouts are costly.

- Key components: Reorder Point = (Average Daily Demand × Lead Time) + Safety Stock.

-

Periodic Review System:

- How it works: Inventory levels are checked at fixed intervals (e.g., weekly, monthly). An order is then placed to bring the stock up to a target level. The order quantity varies.

- Best for: Low-value, high-volume items where continuous monitoring is impractical or too expensive.

- Key components: Order Quantity = Target Stock Level – Current Inventory Level.

-

Economic Order Quantity (EOQ):

- How it works: A mathematical formula that calculates the optimal order size that minimizes the total inventory costs (ordering costs + carrying costs).

- Formula: EOQ = √((2DS)/H), where D = Annual Demand, S = Ordering Cost per order, H = Holding Cost per unit per year.

- Best for: Items with relatively stable demand and costs. Less effective for highly variable demand or custom products.

-

Just-In-Time (JIT) Inventory:

- How it works: Products are ordered and received only when they are needed, minimizing inventory holding. It relies heavily on highly reliable suppliers and efficient production processes.

- Best for: Manufacturing environments focused on lean production, reducing waste and carrying costs. Requires strong supplier relationships and precise demand forecasting.

- Challenges: Highly vulnerable to supply chain disruptions.

-

Material Requirements Planning (MRP):

- How it works: A computer-based system used in manufacturing to plan and schedule the ordering of raw materials and components based on a master production schedule for finished goods. It breaks down demand for finished products into demand for sub-components.

- Best for: Complex manufacturing operations with multiple levels of bills of materials.

-

ABC Analysis:

- How it works: Not an ordering system itself, but a strategy for prioritizing inventory. Items are categorized based on their value or importance (e.g., A-items are high-value, C-items are low-value).

- A-items: Receive the most rigorous ordering control (e.g., ROP, frequent reviews, tight security).

- B-items: Moderate control.

- C-items: Simpler control (e.g., periodic review, bulk ordering).

-

Safety Stock:

- How it works: An extra quantity of inventory held to prevent stockouts due to unexpected variations in demand or lead time. It acts as a buffer.

- Calculation: Influenced by desired service level, demand variability, and lead time variability.

Leveraging Technology in Inventory Ordering

The complexity of modern supply chains and the sheer volume of data make manual inventory ordering increasingly inefficient and prone to error. Technology has become an indispensable ally:

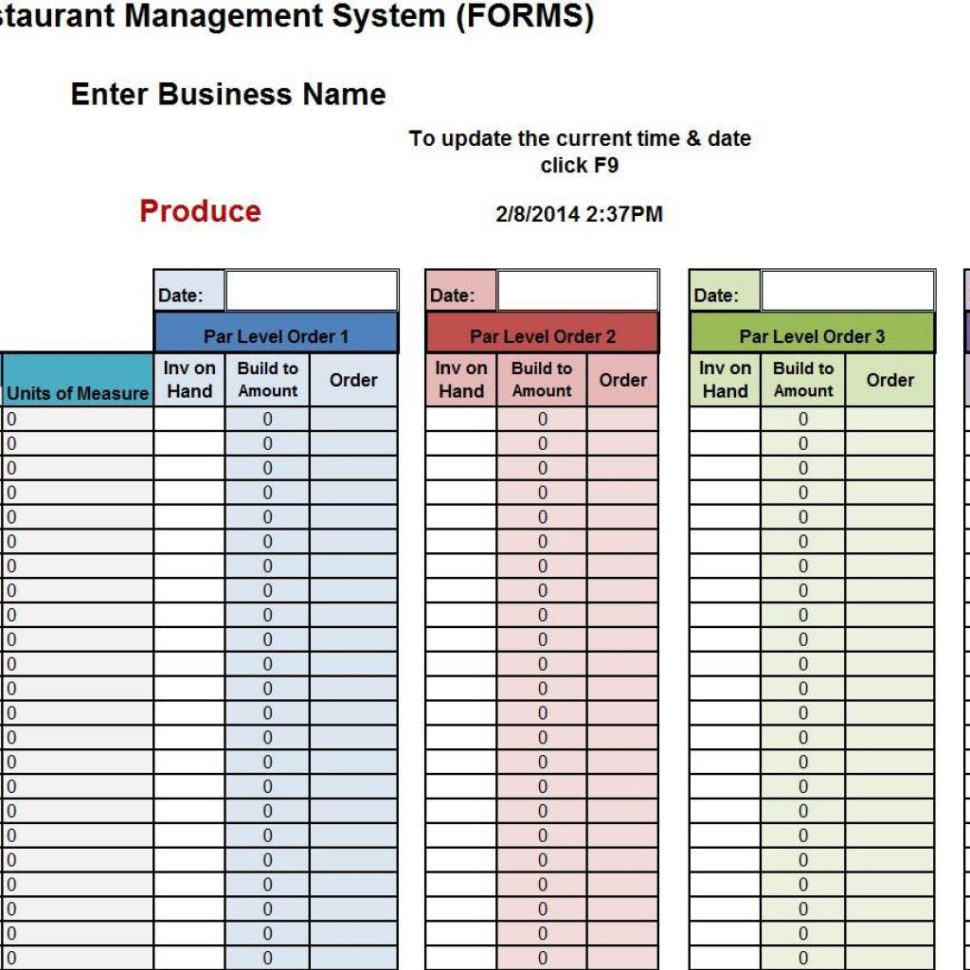

- Inventory Management Systems (IMS) / Warehouse Management Systems (WMS): These software solutions track inventory levels in real-time, automate reorder point calculations, manage purchase orders, and integrate with sales data. They provide a centralized view of all stock movements.

- Enterprise Resource Planning (ERP) Systems: A comprehensive software suite that integrates all facets of a business (finance, HR, sales, production, and inventory). ERP systems provide a holistic view, enabling inventory ordering decisions to be made in conjunction with broader business goals.

- Demand Forecasting Software (AI/ML): Advanced algorithms can analyze vast datasets (historical sales, seasonality, promotions, economic indicators, even social media trends) to generate highly accurate demand forecasts, significantly improving ordering precision.

- Automated Ordering: Many systems can automatically generate purchase orders when inventory reaches a reorder point, sending them directly to pre-approved suppliers. This reduces manual effort and speeds up the replenishment cycle.

- Barcode and RFID Technology: These technologies enable rapid and accurate tracking of inventory as it moves through the supply chain, reducing manual counting errors and providing real-time data for ordering decisions.

- IoT (Internet of Things): Sensors can monitor environmental conditions for perishable goods, track asset location, or even automatically trigger reorders when stock levels are low on a shelf.

The benefits of technological integration are profound: increased accuracy, reduced labor costs, faster decision-making, improved forecasting, and greater transparency across the supply chain.

Best Practices for Optimizing Inventory Ordering

To truly master inventory ordering, businesses should adopt a continuous improvement mindset and adhere to several best practices:

- Invest in Accurate Demand Forecasting: This is the bedrock of effective ordering. Utilize historical data, market research, sales team input, and advanced analytics tools. Regularly review and adjust forecasts.

- Implement Robust Inventory Tracking: Use an IMS or ERP system to maintain real-time, accurate records of all inventory movements. Conduct regular cycle counts or full physical inventories to verify data accuracy.

- Optimize Reorder Points and Quantities: Regularly review and adjust ROPs, safety stock levels, and order quantities based on changes in demand, lead times, and costs. Don’t rely on static parameters.

- Foster Strong Supplier Relationships: Collaborate with suppliers on lead times, order minimums, and delivery schedules. Negotiate favorable terms and explore vendor-managed inventory (VMI) where appropriate.

- Segment Your Inventory (ABC Analysis): Apply different ordering strategies and levels of control to different categories of items based on their value, volume, and criticality.

- Analyze and Understand Costs: Have a clear understanding of your carrying costs, ordering costs, and the true cost of stockouts. This data is vital for making informed decisions.

- Embrace Automation: Automate routine ordering tasks to free up staff for more strategic analysis and decision-making.

- Train Your Team: Ensure that staff involved in inventory management and ordering are well-trained on systems, processes, and the importance of data accuracy.

- Conduct Regular Performance Reviews: Monitor key performance indicators (KPIs) such as inventory turnover rate, stockout rate, order fulfillment rate, and inventory accuracy. Use these insights to identify areas for improvement.

- Build Supply Chain Resilience: Diversify suppliers, consider buffer stock for critical items, and develop contingency plans for potential disruptions.

Challenges in Inventory Ordering

Despite the strategies and technologies available, businesses still face significant challenges:

- Unpredictable Demand: Economic shifts, sudden market trends, and unforeseen events (like pandemics) can render even the best forecasts inaccurate.

- Supply Chain Volatility: Geopolitical events, natural disasters, and logistical bottlenecks can disrupt lead times and supplier reliability.

- Data Accuracy Issues: Inaccurate inventory counts, errors in data entry, or fragmented systems can undermine even sophisticated ordering models.

- Cost vs. Service Trade-offs: Balancing the desire for high customer service (requiring more safety stock) with the need to minimize inventory holding costs is a constant dilemma.

- Technological Integration: Implementing and integrating new inventory systems can be complex, costly, and require significant organizational change management.

Conclusion

Business inventory ordering is far more than a transactional process; it is a strategic function that underpins operational efficiency, financial stability, and customer loyalty. In an increasingly dynamic global marketplace, the ability to accurately forecast demand, optimize order quantities, and leverage technology for real-time insights is paramount.

By understanding the key factors at play, adopting appropriate models, and embracing best practices, businesses can transform their inventory ordering from a reactive chore into a proactive competitive advantage. The future of inventory ordering will undoubtedly see further advancements in AI, machine learning, and IoT, offering even greater precision and automation. However, the fundamental principles of balancing supply and demand, minimizing costs, and satisfying customers will remain at its core, making the mastery of this art a perpetual and critical endeavor for sustained business success.