The Inventory Abbreviation Crossword: Decoding Business Strategy for Optimal Operations

In the intricate world of business, efficient inventory management is not merely a logistical task; it’s a strategic imperative that directly impacts profitability, customer satisfaction, and operational fluidity. Yet, navigating the myriad strategies, methodologies, and systems can feel like deciphering a complex puzzle, often compounded by a dense lexicon of abbreviations. Like a challenging crossword, each acronym represents a crucial piece of the larger picture, and understanding how they interlock is key to unlocking optimal business performance.

This article aims to provide a comprehensive guide to the essential abbreviations in business inventory strategy. We will explore what each acronym stands for, its significance, and how it contributes to a coherent and effective inventory management system. By the end, you’ll not only understand these terms but also appreciate how mastering this "inventory abbreviation crossword" can be a powerful tool for strategic decision-making.

Why Abbreviations are Crucial in Inventory Management

Before delving into specific terms, it’s vital to understand why these abbreviations are so prevalent.

- Efficiency in Communication: In fast-paced business environments, acronyms provide a shorthand for complex concepts, streamlining communication between departments, suppliers, and stakeholders.

- Standardization: Many abbreviations represent industry-standard methodologies or systems, ensuring a common understanding across different companies and sectors.

- Strategic Focus: By encapsulating entire strategies or systems, abbreviations help professionals quickly reference and apply specific approaches without lengthy explanations.

- Learning and Development: For newcomers, understanding these terms is the first step in grasping the foundational principles of inventory management.

Think of each abbreviation as a concise clue in our inventory crossword. Solving them individually is useful, but the real power comes from seeing how they connect horizontally and vertically to form a complete operational strategy.

The Core Inventory Abbreviation Crossword: Clues and Answers

Let’s break down the most common and critical abbreviations, categorizing them for better understanding.

I. Core Inventory Identification & Valuation

-

SKU (Stock Keeping Unit):

- Definition: A unique identifier for each distinct product and service that can be purchased. SKUs are assigned to the smallest unit of a product that can be sold (e.g., a specific model of a smartphone in a particular color and storage size).

- Significance: Fundamental for tracking inventory levels, sales, and purchasing. Without accurate SKUs, effective inventory control is impossible. It’s the most basic "word" in our crossword.

- Connection: Often linked to POS systems and WMS for real-time tracking.

-

FIFO (First-In, First-Out):

- Definition: An inventory valuation method assuming that the first goods purchased or produced are the first ones sold, used, or otherwise disposed of.

- Significance: Preferred for perishable goods or products with a shelf life, ensuring older stock is moved first to minimize spoilage or obsolescence. It also impacts financial reporting by influencing the Cost of Goods Sold (COGS) and ending inventory value.

- Connection: Directly influences financial statements and warehouse layout (e.g., ensuring older stock is easily accessible).

-

LIFO (Last-In, First-Out):

- Definition: An inventory valuation method assuming that the last goods purchased or produced are the first ones sold, used, or otherwise disposed of.

- Significance: While less common for physical inventory flow (except in specific industries like mining), it was historically used in accounting for tax advantages during periods of inflation (though generally prohibited under IFRS).

- Connection: Primarily a financial accounting method rather than a physical inventory strategy, but understanding its contrast with FIFO is crucial.

II. Inventory Planning & Control Strategies

-

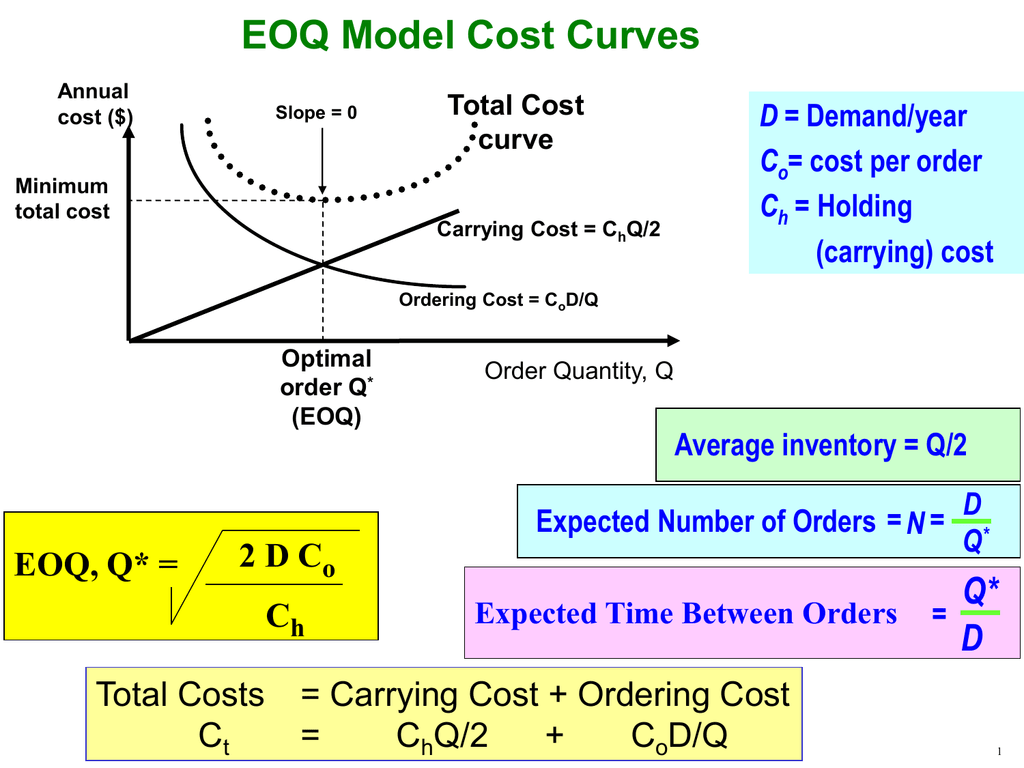

EOQ (Economic Order Quantity):

- Definition: A formula used to calculate the optimal quantity of inventory to order at a time to minimize total inventory costs (holding costs and ordering costs).

- Significance: A cornerstone of traditional inventory management, aiming to strike a balance between having too much stock (high holding costs) and ordering too frequently (high ordering costs).

- Connection: Often used in conjunction with ROP and safety stock calculations.

-

ROP (Reorder Point):

- Definition: The minimum level of inventory that triggers a new order. It’s calculated based on lead time demand and safety stock.

- Significance: Prevents stockouts by ensuring that new orders are placed well before current stock runs out, allowing for lead time.

- Connection: Works hand-in-hand with EOQ to determine when to order and how much to order.

-

JIT (Just-In-Time):

- Definition: A lean inventory strategy where goods are ordered and received only as they are needed for production or sale, minimizing inventory holding costs and waste.

- Significance: Reduces carrying costs, waste, and obsolescence. Requires extremely tight coordination with suppliers and highly reliable supply chains.

- Connection: A core component of lean manufacturing and often facilitated by strong SCM and ERP systems.

-

MRP (Material Requirements Planning):

- Definition: A computer-based system used to manage and plan manufacturing processes, specifically identifying what materials are needed, how much is needed, and when they are needed to meet production schedules.

- Significance: Essential for complex manufacturing operations, ensuring raw materials and components are available when required, avoiding production delays.

- Connection: A foundational component of many ERP systems.

-

MRP II (Manufacturing Resource Planning):

- Definition: An extension of MRP that integrates all aspects of the manufacturing process, including finance, marketing, and human resources, into a single system.

- Significance: Provides a broader view of manufacturing operations, linking production planning with financial and other business functions.

- Connection: A stepping stone towards full ERP integration.

-

ABC Analysis:

- Definition: An inventory categorization technique that divides inventory into three categories (A, B, and C) based on their value or importance. ‘A’ items are high-value, low-volume; ‘C’ items are low-value, high-volume; ‘B’ items are in between.

- Significance: Allows businesses to focus their inventory control efforts on the most critical items, optimizing resources and reducing risk. ‘A’ items receive the most rigorous control.

- Connection: Informs decisions about safety stock levels, order frequency, and physical security for different inventory categories.

-

VMI (Vendor-Managed Inventory):

- Definition: A supply chain strategy where the supplier (vendor) is responsible for maintaining the inventory levels of their products at the customer’s location.

- Significance: Can lead to reduced stockouts, lower inventory holding costs for the customer, and improved forecast accuracy through collaboration.

- Connection: Requires strong trust and data sharing between buyer and supplier, often facilitated by integrated SCM systems.

III. Systems & Technology

-

ERP (Enterprise Resource Planning):

- Definition: A comprehensive software system that integrates all facets of an operation, including product planning, development, manufacturing, sales, marketing, and inventory management, into a single database and user interface.

- Significance: Provides a holistic view of the business, enhancing data accuracy, streamlining processes, and improving decision-making across all departments, including inventory.

- Connection: Often incorporates modules for MRP, WMS, and SCM, acting as the central hub for most business data.

-

WMS (Warehouse Management System):

- Definition: A software application designed to support and optimize warehouse or distribution center operations, from the time goods or materials enter a warehouse until they move out.

- Significance: Improves efficiency in receiving, putaway, picking, packing, and shipping, leading to better space utilization, reduced labor costs, and faster order fulfillment.

- Connection: Integrates with ERP systems to provide real-time inventory visibility.

-

SCM (Supply Chain Management):

- Definition: The broad management of the flow of goods and services, encompassing all processes that transform raw materials into final products, from procurement to customer delivery.

- Significance: Optimizes the entire network of suppliers, manufacturers, distributors, and customers, leading to cost reductions, improved efficiency, and enhanced customer satisfaction. Inventory management is a critical component of SCM.

- Connection: JIT, VMI, and ERP systems all play vital roles in effective SCM.

-

RFID (Radio-Frequency Identification):

- Definition: A technology that uses electromagnetic fields to automatically identify and track tags attached to objects.

- Significance: Enables real-time, accurate inventory tracking without line-of-sight scanning, greatly improving inventory visibility, reducing manual counting, and combating theft.

- Connection: A technology that enhances the capabilities of WMS and ERP systems for physical inventory control.

-

POS (Point of Sale):

- Definition: The place where a retail transaction is completed. A POS system records the sale, updates inventory levels, and often manages customer data.

- Significance: Provides real-time sales data, which is crucial for accurate demand forecasting and automatic inventory replenishment.

- Connection: Feeds critical data into inventory management systems, helping to trigger ROP and inform EOQ calculations.

IV. Performance & Analytics

- KPI (Key Performance Indicator):

- Definition: A measurable value that demonstrates how effectively a company is achieving key business objectives.

- Significance: For inventory, KPIs might include inventory turnover rate, stockout rate, order fulfillment lead time, inventory accuracy, and carrying costs. They provide metrics for evaluating the success of inventory strategies.

- Connection: Used to monitor the effectiveness of all other inventory strategies and systems, driving continuous improvement.

Solving the Crossword: Interlocking Strategies

Understanding these abbreviations individually is like knowing the definition of each word in a crossword. The real challenge, and the real value, comes from seeing how they intersect and form a cohesive strategy.

- A business might use MRP within an ERP system to plan production. This system then uses SKU data to track individual items.

- JIT principles might guide procurement decisions, which are then formalized through VMI agreements with suppliers, all monitored by SCM software.

- EOQ and ROP calculations are informed by sales data from POS systems and inventory levels tracked by a WMS.

- ABC Analysis helps prioritize inventory, determining which SKUs need tighter control (perhaps even using RFID for high-value ‘A’ items) and which can be managed with less intensity.

- Ultimately, the success of all these strategies is measured by KPIs, which provide feedback loops for continuous optimization.

This interconnectedness highlights that inventory management is not a collection of isolated tasks but a dynamic ecosystem where each component influences the others.

The Benefits of Mastering the Inventory Abbreviation Crossword

Businesses that effectively "solve" this crossword reap significant rewards:

- Reduced Costs: Minimizing holding costs (JIT, EOQ), optimizing ordering (EOQ, ROP), and reducing waste contribute directly to the bottom line.

- Improved Efficiency: Streamlined processes from procurement to dispatch (MRP, WMS, ERP) lead to faster operations and better resource utilization.

- Enhanced Customer Satisfaction: Fewer stockouts, faster fulfillment, and consistent product availability (ROP, SCM) translate into happier customers.

- Better Decision-Making: Real-time data and integrated systems (ERP, POS) provide insights for strategic planning and agile responses to market changes.

- Increased Competitiveness: An optimized inventory system allows a business to be more responsive, cost-effective, and reliable than its competitors.

Challenges and Future Directions

While mastering these abbreviations is crucial, it’s not without its challenges. Data accuracy, the complexity of integrating diverse systems, and the need for continuous training are ongoing hurdles. The future of inventory management will likely see an increased reliance on AI and Machine Learning (ML) for demand forecasting, predictive analytics, and automated decision-making, further evolving the lexicon.

Conclusion

The world of business inventory strategy is rich with abbreviations, each representing a critical concept or tool. Like a well-designed crossword, these terms are not random; they are interconnected, forming a comprehensive framework for managing one of a company’s most valuable assets. By understanding the meaning and strategic importance of SKU, FIFO, EOQ, JIT, MRP, ERP, WMS, SCM, RFID, POS, KPI, and others, businesses can move beyond mere logistics to truly optimize their operations.

Mastering this "inventory abbreviation crossword" empowers professionals to communicate effectively, implement robust strategies, leverage advanced technologies, and ultimately drive their organizations towards greater efficiency, profitability, and sustained success in an ever-evolving market. It’s an ongoing puzzle, but one with immense rewards for those who commit to solving it.