Mastering the Jargon Maze: Business Inventory Strategy Abbreviations through Crossword Puzzles

In the dynamic world of business, efficient inventory management is not merely a logistical task; it’s a strategic imperative that directly impacts profitability, customer satisfaction, and overall operational efficiency. Companies constantly seek to optimize their inventory levels, balancing the costs of holding stock against the risks of stockouts. This pursuit has led to the development of numerous sophisticated inventory strategies, each with its unique principles, methodologies, and, inevitably, its own set of abbreviations.

For newcomers to supply chain management or even seasoned professionals looking to broaden their expertise, the sheer volume of acronyms and initialisms can be daunting. From JIT to EOQ, MRP to ERP, and FIFO to LIFO, the lexicon of inventory management can feel like a foreign language. This is where an innovative and engaging learning tool comes into play: the business inventory strategy abbreviation crossword. By transforming complex terminology into an interactive puzzle, crosswords offer a powerful, memorable, and even enjoyable way to master the essential language of inventory strategy.

This article will delve into the critical role of inventory management, explore key business inventory strategies and their associated abbreviations, highlight the importance of understanding this jargon, and finally, demonstrate how crossword puzzles can serve as an exceptional tool for learning, reinforcing, and ultimately mastering these crucial inventory concepts.

The Crucial Role of Inventory Management

Inventory, in its essence, represents a company’s stored goods, whether raw materials, work-in-progress, or finished products. Managing this inventory effectively is a delicate balancing act. Too much inventory ties up capital, incurs storage costs (warehousing, insurance, security), and risks obsolescence or damage. Too little inventory, on the other hand, can lead to stockouts, lost sales, production delays, and ultimately, dissatisfied customers.

Effective inventory management aims to:

- Minimize Costs: Reduce holding costs, ordering costs, and setup costs.

- Maximize Customer Service: Ensure products are available when customers want them.

- Improve Efficiency: Streamline operations and reduce waste.

- Enhance Cash Flow: Free up capital tied in inventory for other investments.

Achieving this balance requires strategic thinking and the application of various inventory control techniques, each often condensed into a convenient, yet sometimes confusing, abbreviation.

Key Business Inventory Strategies and Their Abbreviations

Let’s explore some of the most common and influential inventory strategies and their abbreviations that form the backbone of modern supply chain operations. Understanding these is the first step towards effective management and, subsequently, towards conquering any related crossword puzzle.

1. Just-In-Time (JIT)

- Full Name: Just-In-Time

- Concept: A lean manufacturing strategy that aims to reduce inventory costs and improve efficiency by receiving goods only as they are needed for production or sale, rather than maintaining large stockpiles. This minimizes waste and storage costs but requires highly reliable suppliers and demand forecasting.

- Why it’s used: Reduces inventory holding costs, identifies production bottlenecks, improves quality by reducing defects.

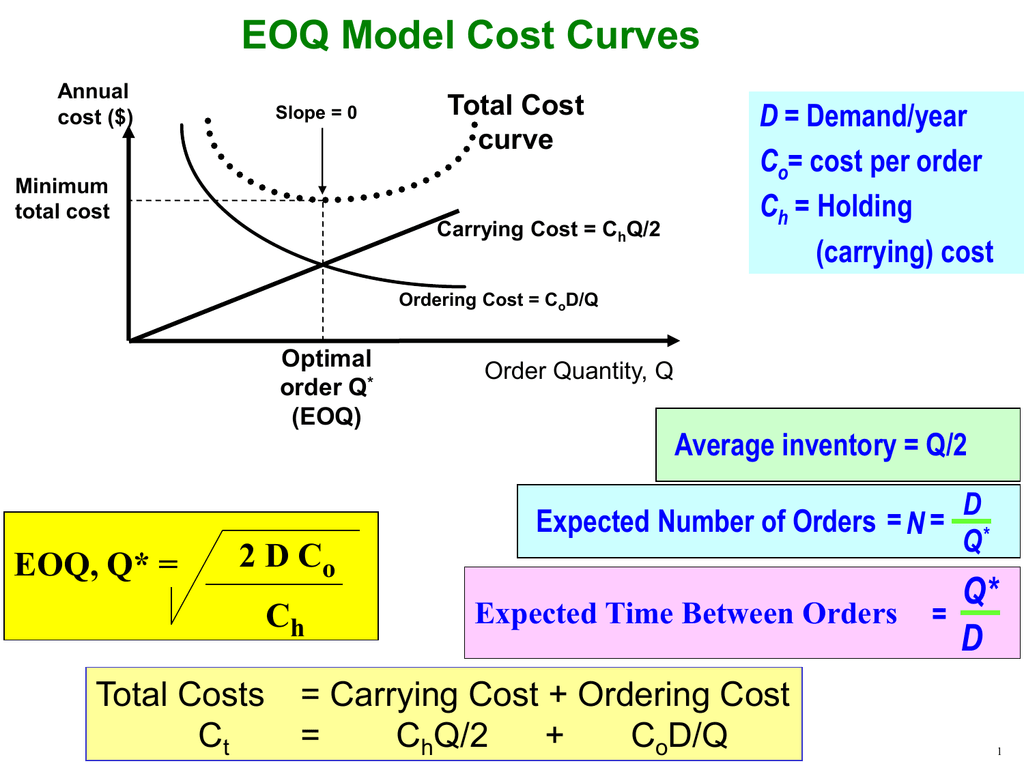

2. Economic Order Quantity (EOQ)

- Full Name: Economic Order Quantity

- Concept: A formula used in inventory management to determine the optimal order quantity that minimizes the total inventory costs, including holding costs and ordering costs. It assumes constant demand and lead time.

- Why it’s used: Helps companies decide how much to order to keep costs down while meeting demand.

3. Materials Requirements Planning (MRP)

- Full Name: Materials Requirements Planning

- Concept: A production planning and inventory control system used to manage manufacturing processes. It ensures that materials are available for production and products are available for delivery to customers. MRP calculates what materials are needed, how much, and when.

- Why it’s used: Efficiently plans raw material procurement and production scheduling.

4. Manufacturing Resource Planning (MRP II)

- Full Name: Manufacturing Resource Planning

- Concept: An advanced version of MRP that integrates all aspects of a manufacturing operation, including production planning, master scheduling, material requirements planning, capacity planning, and financial reporting. It’s a broader system that considers more than just materials.

- Why it’s used: Provides a comprehensive planning system for all manufacturing resources, improving overall efficiency and decision-making.

5. Enterprise Resource Planning (ERP)

- Full Name: Enterprise Resource Planning

- Concept: A software system that integrates all facets of an enterprise, including planning, manufacturing, sales, marketing, and finance. Inventory management is a core module within an ERP system, providing a holistic view of the business.

- Why it’s used: Creates a unified system for managing business processes, improving data consistency and inter-departmental communication.

6. First-In, First-Out (FIFO)

- Full Name: First-In, First-Out

- Concept: An inventory valuation method where it’s assumed that the first goods purchased or produced are the first ones sold. This method typically results in higher reported profits during periods of rising costs.

- Why it’s used: Often reflects the actual flow of goods (especially perishables) and is generally preferred for its straightforwardness and alignment with physical inventory movement.

7. Last-In, First-Out (LIFO)

- Full Name: Last-In, First-Out

- Concept: An inventory valuation method where it’s assumed that the last goods purchased or produced are the first ones sold. This method typically results in lower reported profits (and thus lower taxes) during periods of rising costs.

- Why it’s used: Can be advantageous for tax purposes in inflationary environments, though less common internationally due to IFRS restrictions.

8. ABC Analysis

- Full Name: ABC Analysis (often no full expansion, but refers to A, B, C categories)

- Concept: An inventory categorization technique that divides items into three categories based on their value and impact on the business: ‘A’ items (high value, low quantity), ‘B’ items (medium value, medium quantity), and ‘C’ items (low value, high quantity). This allows for differentiated management efforts.

- Why it’s used: Prioritizes inventory control efforts, focusing more attention on high-value items.

9. Vendor Managed Inventory (VMI)

- Full Name: Vendor Managed Inventory

- Concept: A supply chain where the vendor (supplier) is responsible for maintaining the inventory level at the customer’s location. The vendor monitors the customer’s inventory and replenishes stock as needed.

- Why it’s used: Reduces customer’s inventory management burden, improves supply chain efficiency, and strengthens vendor-customer relationships.

10. Safety Stock (SS)

- Full Name: Safety Stock

- Concept: An extra quantity of inventory held to prevent stockouts due to variations in demand or lead time. It acts as a buffer against unforeseen fluctuations.

- Why it’s used: Mitigates risks of supply chain disruptions and ensures continuous operations.

11. Lead Time (LT)

- Full Name: Lead Time

- Concept: The time interval between the initiation of a process (e.g., placing an order) and its completion (e.g., receiving the goods).

- Why it’s used: Critical for planning and scheduling, especially in JIT and MRP systems.

12. Reorder Point (ROP)

- Full Name: Reorder Point

- Concept: The minimum level of inventory that triggers a new order for an item. It’s calculated based on demand during lead time plus safety stock.

- Why it’s used: Ensures timely replenishment to avoid stockouts.

The Power of Abbreviations in Business

Abbreviations are ubiquitous in the business world, especially in specialized fields like supply chain and operations management. They serve several critical functions:

- Efficiency: They allow for quicker communication and documentation.

- Standardization: They provide a common language for professionals within an industry.

- Professionalism: Mastery of these terms signals expertise and understanding.

However, this efficiency comes at a cost: a steep learning curve for those unfamiliar with the jargon. Misunderstanding an abbreviation can lead to significant errors in strategy, planning, and execution.

Crosswords: An Innovative Tool for Mastering Inventory Abbreviation Strategy

This is where the humble crossword puzzle transforms into a powerful educational instrument. Far from being just a leisure activity, crosswords engage the brain in a way that rote memorization often fails to achieve.

Why Crosswords are Effective for Learning Abbreviations:

- Active Recall: Instead of passively reading definitions, crosswords require active retrieval of information. This process strengthens memory pathways.

- Contextual Learning: Clues often provide context, allowing learners to associate the abbreviation not just with its full form, but also with its function and implications.

- Pattern Recognition: Filling in letters helps in recognizing the structure of the abbreviation and its full form.

- Engagement and Gamification: The puzzle format makes learning enjoyable and less like a chore. This increased engagement can lead to better retention.

- Identification of Knowledge Gaps: If a learner struggles with a particular clue, it immediately highlights an area where more study is needed.

- Reinforcement: Repeated exposure to the same abbreviations in different puzzle contexts reinforces learning.

How Crosswords Work for Inventory Abbreviations:

A typical crossword puzzle would feature clues that define, describe, or hint at the full name or the concept behind an abbreviation. The answer, often limited by the number of letters in the grid, would be the abbreviation itself or a key part of its full form.

Crafting Effective Crossword Clues for Inventory Strategy Abbreviations

To make a truly effective learning tool, the clues must be well-crafted. Here are examples of how clues for the abbreviations discussed above might look:

Across:

- JIT (3 Letters) – Inventory strategy aimed at minimizing stock by receiving goods only as needed.

- MRP (3 Letters) – Planning system for materials used in manufacturing.

- FIFO (4 Letters) – Inventory costing method assuming oldest goods are sold first.

- VMI (3 Letters) – Supply chain arrangement where the supplier manages stock at the customer’s site.

- ROP (3 Letters) – Inventory level that triggers a new order.

Down:

- EOQ (3 Letters) – Formula determining the optimal quantity to order to minimize costs.

- ERP (3 Letters) – Software integrating all facets of an enterprise, including inventory.

- LIFO (4 Letters) – Inventory costing method assuming newest goods are sold first.

- ABC (3 Letters) – Analysis method categorizing inventory by value (e.g., high, medium, low).

- SS (2 Letters) – Extra inventory held to prevent stockouts.

- LT (2 Letters) – The time taken from placing an order to receiving it.

- MRPII (5 Letters) – Broader planning system that extends beyond just materials to include other resources.

Tips for Creating Great Clues:

- Vary Difficulty: Include some straightforward definitions and some more conceptual clues.

- Use Context: Describe the practical application or benefit of the strategy.

- Mix Full Forms and Concepts: Sometimes ask for the abbreviation, other times for a word within the full form.

- Be Precise: Ensure clues are unambiguous.

Conclusion

In the complex landscape of modern business, a robust understanding of inventory management strategies is non-negotiable. The plethora of abbreviations associated with these strategies can be a significant hurdle, but it doesn’t have to be. By embracing innovative learning methods like the business inventory strategy abbreviation crossword, professionals can transform a potential stumbling block into a stepping stone.

Crosswords offer an engaging, effective, and memorable way to master the critical jargon of inventory management. They foster active recall, contextual understanding, and self-assessment, ultimately empowering individuals to navigate the intricacies of supply chain operations with confidence and expertise. So, next time you’re faced with a new set of business abbreviations, consider turning them into a puzzle – you might just find that learning has never been so strategic, or so much fun.