Mastering the Lexicon of Efficiency: A Deep Dive into Business Inventory Strategy Abbreviations

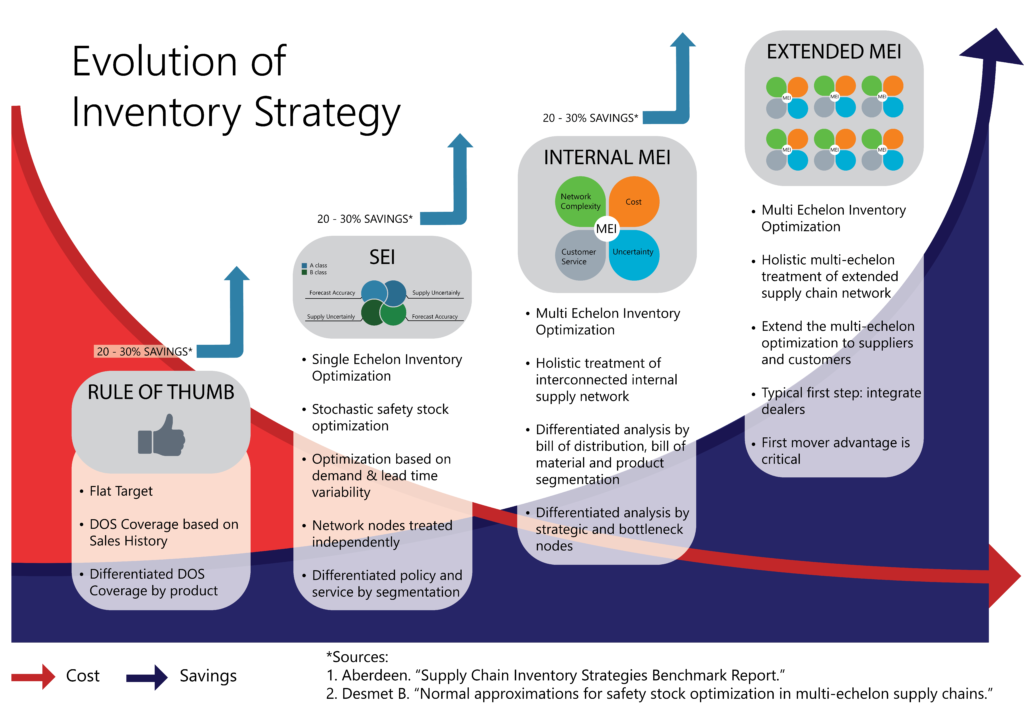

In the intricate world of supply chain management, inventory stands as both a vital asset and a potential liability. It’s the lifeblood that fuels production, satisfies customer demand, and enables growth. However, poorly managed inventory can lead to exorbitant carrying costs, obsolescence, stockouts, and ultimately, lost revenue. To navigate this complex landscape, businesses rely on a diverse array of strategies, often encapsulated in precise, industry-standard abbreviations. These acronyms are more than just shorthand; they represent sophisticated methodologies, critical metrics, and advanced technological frameworks designed to optimize the flow and storage of goods.

This article delves into the crucial business inventory strategy abbreviations, unpacking their meanings, strategic implications, and how they contribute to a lean, resilient, and profitable supply chain. Understanding this specialized lexicon is not merely about memorizing terms; it’s about grasping the underlying principles that drive operational excellence and competitive advantage.

The "Why" Behind the Abbreviation: Efficiency and Standardization

Before dissecting individual terms, it’s essential to understand why abbreviations are so prevalent in inventory management.

- Efficiency in Communication: In fast-paced business environments, quick and clear communication is paramount. Abbreviations allow professionals to convey complex ideas rapidly without sacrificing precision.

- Standardization: They create a common language across departments, companies, and even international supply chains, reducing ambiguity and fostering a shared understanding of processes and objectives.

- Conciseness in Documentation: Reports, dashboards, and system interfaces often use abbreviations to present critical data succinctly, making it easier for managers to absorb information and make timely decisions.

- Industry Best Practices: Many abbreviations represent established methodologies that have proven effective across various sectors, enabling businesses to adopt and adapt successful strategies.

Now, let’s explore some of the most pivotal abbreviations shaping modern inventory strategy.

Core Inventory Planning and Optimization Abbreviations

These abbreviations relate directly to how businesses plan for, manage, and optimize their inventory levels.

-

MRP (Material Requirements Planning):

- Definition: A system used to manage manufacturing processes. It ensures that materials are available for production and products are available for delivery to customers. MRP calculates the quantities and timings of raw materials and components needed to fulfill a Master Production Schedule (MPS).

- Strategic Implication: MRP is foundational for production planning. It minimizes inventory holding costs by ensuring materials arrive just in time for production, preventing both shortages and excessive stock. It’s crucial for complex manufacturing with multiple Bill of Materials (BOM) levels.

-

DRP (Distribution Requirements Planning):

- Definition: A method used to plan the distribution of finished goods from manufacturing plants to warehouses and then to retail outlets or customers. It extends the logic of MRP to the distribution network.

- Strategic Implication: DRP optimizes the flow of finished products, ensuring that the right products are in the right place at the right time to meet customer demand, while minimizing transportation and warehousing costs. It’s vital for businesses with extensive distribution networks.

-

MPS (Master Production Schedule):

- Definition: A plan that specifies how many of each product are to be produced during a given period. It drives the MRP process and is a key input for production capacity planning.

- Strategic Implication: The MPS acts as the central orchestrator for manufacturing and supply chain activities. A well-constructed MPS balances demand forecasts with production capacity, leading to efficient resource utilization and stable inventory levels.

-

BOM (Bill of Materials):

- Definition: A comprehensive list of the raw materials, components, and assemblies required to construct, manufacture, or repair a product. It often includes quantities and hierarchical relationships.

- Strategic Implication: The BOM is essential for accurate cost accounting, procurement, and inventory planning. Any inaccuracies can lead to production delays, incorrect material orders, and inflated costs.

-

EOQ (Economic Order Quantity):

- Definition: A formula that calculates the optimal quantity of inventory to order to minimize the total inventory costs (ordering costs + holding costs).

- Strategic Implication: EOQ helps businesses strike a balance between placing too many small orders (high ordering costs) and too few large orders (high holding costs). While a classic model, it remains a useful benchmark, especially for stable demand items.

-

ROP (Reorder Point):

- Definition: The inventory level at which a new order should be placed to replenish stock. It typically accounts for lead time and demand during that lead time.

- Strategic Implication: ROP is a critical operational trigger that prevents stockouts. Calculating it accurately involves understanding lead times from suppliers and the variability of demand.

-

SS (Safety Stock):

- Definition: Extra inventory held to mitigate the risk of stockouts due to uncertainties in demand or supply (e.g., unexpected spikes in sales, supplier delays).

- Strategic Implication: Safety stock is an insurance policy against unforeseen disruptions. While it incurs holding costs, it protects against lost sales and customer dissatisfaction. Optimizing SS levels is a continuous challenge.

-

JIT (Just-In-Time):

- Definition: A lean inventory management strategy where materials and components are delivered exactly when needed for production or sale, minimizing inventory holding costs and waste.

- Strategic Implication: JIT revolutionizes inventory management by aiming for zero inventory. It requires highly reliable suppliers, precise demand forecasting, and efficient logistics. While offering significant cost savings, it can be vulnerable to supply chain disruptions.

-

VMI (Vendor Managed Inventory):

- Definition: A system where the supplier (vendor) is responsible for maintaining the inventory levels of their products at the customer’s location. The vendor monitors stock levels and replenishes them as needed.

- Strategic Implication: VMI fosters closer collaboration between suppliers and customers, leading to improved forecasting, reduced stockouts, lower inventory levels for the customer, and better service. It shifts inventory management responsibility and often benefits both parties.

-

CPFR (Collaborative Planning, Forecasting, and Replenishment):

- Definition: A business practice that combines the intelligence of multiple trading partners (e.g., manufacturers, distributors, retailers) in the planning and fulfillment of customer demand.

- Strategic Implication: CPFR aims to significantly improve supply chain efficiency and effectiveness by sharing forecasts and inventory data, reducing bullwhip effect, and optimizing inventory across the entire chain.

Inventory Cost and Valuation Abbreviations

Understanding the financial implications of inventory requires familiarity with these terms.

-

LIFO (Last-In, First-Out):

- Definition: An accounting method where the most recently purchased inventory items are assumed to be the first ones sold.

- Strategic Implication: In periods of rising costs, LIFO results in a higher Cost of Goods Sold (COGS) and lower taxable income, which can be advantageous for tax purposes. However, it may not reflect the actual physical flow of goods.

-

FIFO (First-In, First-Out):

- Definition: An accounting method where the oldest inventory items (first ones purchased) are assumed to be the first ones sold.

- Strategic Implication: FIFO generally reflects the physical flow of most goods, especially perishables. In periods of rising costs, it results in a lower COGS and higher taxable income, showing a higher profit on financial statements.

-

WAC (Weighted Average Cost):

- Definition: An accounting method that calculates the average cost of all inventory available for sale, and uses this average to determine the COGS and the value of ending inventory.

- Strategic Implication: WAC smooths out cost fluctuations and is often considered a compromise between LIFO and FIFO, providing a more stable representation of inventory costs.

-

COGS (Cost of Goods Sold):

- Definition: The direct costs attributable to the production of the goods sold by a company. This amount includes the cost of the materials and labor directly used to create the good.

- Strategic Implication: COGS is a critical metric for profitability analysis. Effective inventory management directly impacts COGS by minimizing waste, optimizing procurement, and controlling production costs.

-

CC (Carrying Cost) / HC (Holding Cost):

- Definition: The costs associated with holding inventory in stock. This includes warehousing, insurance, obsolescence, damage, depreciation, and the opportunity cost of capital tied up in inventory.

- Strategic Implication: High carrying costs erode profitability. Strategies like JIT and optimized inventory levels aim to reduce CC, freeing up capital and space.

-

OC (Ordering Cost):

- Definition: The costs associated with placing an order for inventory. This includes administrative costs, processing fees, transportation costs, and inspection costs.

- Strategic Implication: Ordering costs must be balanced against carrying costs. EOQ helps find the sweet spot to minimize the sum of both.

Inventory Performance and Control Abbreviations

These abbreviations are used to measure, classify, and control inventory performance.

-

OTIF (On-Time, In-Full):

- Definition: A key performance indicator (KPI) that measures the percentage of orders delivered to customers exactly when promised (on-time) and with the complete quantity of items requested (in-full).

- Strategic Implication: OTIF is a critical measure of supply chain reliability and customer satisfaction. High OTIF rates indicate efficient inventory management, accurate forecasting, and robust logistics.

-

SKU (Stock Keeping Unit):

- Definition: A unique identifier for each distinct product and service that can be purchased. It allows businesses to track inventory levels, sales, and returns for specific items.

- Strategic Implication: SKUs are fundamental for granular inventory control. Effective SKU management is essential for accurate inventory counts, efficient picking, and detailed sales analysis.

-

ABC Analysis:

- Definition: An inventory categorization technique that divides items into three categories based on their value and importance to the business:

- A-items: High value, low volume (e.g., 20% of items account for 80% of value).

- B-items: Medium value, medium volume.

- C-items: Low value, high volume (e.g., 50% of items account for 5% of value).

- Strategic Implication: ABC analysis allows businesses to prioritize inventory control efforts. A-items receive the most stringent control, frequent checks, and accurate forecasting, while C-items might have simpler, less frequent oversight.

- Definition: An inventory categorization technique that divides items into three categories based on their value and importance to the business:

-

FEFO (First-Expired, First-Out):

- Definition: An inventory rotation method where items with the earliest expiration dates are sold or used first, regardless of when they were received.

- Strategic Implication: FEFO is crucial for industries dealing with perishable goods (food, pharmaceuticals) or products with limited shelf lives. It minimizes waste due to spoilage or obsolescence, ensuring product freshness and safety.

-

SOP (Sales and Operations Planning):

- Definition: An integrated business management process that bridges strategic planning and operational execution. It ensures that the sales, marketing, and production plans are aligned with the company’s financial goals.

- Strategic Implication: SOP is a cross-functional process that balances supply and demand. It uses demand forecasts to inform production and inventory decisions, aiming to optimize resource allocation, reduce inventory levels, and improve customer service.

Enabling Technologies and Systems Abbreviations

These abbreviations represent the technological backbone supporting modern inventory strategies.

-

ERP (Enterprise Resource Planning):

- Definition: A suite of integrated software applications that manage and integrate core business processes, including inventory management, across an entire organization.

- Strategic Implication: ERP systems provide a unified view of inventory across the supply chain, enabling real-time tracking, improved forecasting, and streamlined operations by integrating data from various departments.

-

WMS (Warehouse Management System):

- Definition: A software application designed to support and optimize warehouse operations, from receiving and putaway to picking, packing, and shipping.

- Strategic Implication: WMS improves warehouse efficiency, accuracy, and space utilization. It reduces errors, speeds up order fulfillment, and provides precise inventory location data.

-

RFID (Radio-Frequency Identification):

- Definition: A technology that uses electromagnetic fields to automatically identify and track tags attached to objects. These tags contain electronically stored information.

- Strategic Implication: RFID offers superior inventory visibility and accuracy compared to manual scanning or barcodes. It enables automated inventory counts, real-time tracking, and reduces shrinkage, especially in large-scale operations.

-

EDI (Electronic Data Interchange):

- Definition: The electronic exchange of business documents (e.g., purchase orders, invoices, shipping notices) in a standardized format between computer systems of different companies.

- Strategic Implication: EDI automates communication with trading partners, significantly reducing administrative costs, processing errors, and lead times in the supply chain, thereby improving inventory flow and collaboration.

The Holistic View: Beyond the Acronym

While understanding these abbreviations is crucial, true mastery lies in recognizing their interconnectedness. A robust inventory strategy doesn’t rely on a single acronym but rather a synergistic combination of several. For instance, an effective MRP system is only as good as its MPS input, which in turn is informed by accurate demand forecasts potentially derived from CPFR activities. Safety stock levels might be optimized using an EOQ model, all while being managed through an ERP system and tracked via a WMS utilizing RFID technology.

Challenges and Future Trends

The landscape of inventory management is constantly evolving. Businesses face ongoing challenges such as:

- Global Supply Chain Volatility: Geopolitical events, natural disasters, and pandemics underscore the need for resilient inventory strategies.

- Sustainability (ESG): Growing pressure to reduce environmental impact drives demand for leaner, more efficient, and ethically sourced inventory.

- Digitalization: The rise of AI, Machine Learning (ML), and the Internet of Things (IoT) promises even more sophisticated forecasting, automated inventory adjustments, and predictive analytics.

- Omnichannel Fulfillment: Managing inventory across multiple sales channels (online, physical stores, marketplaces) creates complex logistical challenges.

Conclusion

The world of business inventory strategy is rich with specialized terminology, and its abbreviations are the linguistic shortcuts that enable efficient communication and execution. From foundational planning methodologies like MRP and DRP to sophisticated financial valuation techniques like FIFO and LIFO, and cutting-edge technologies like RFID and ERP, each acronym represents a vital component in the quest for optimal inventory performance.

By understanding these abbreviations, business professionals gain a clearer insight into the strategies that drive operational efficiency, minimize costs, enhance customer satisfaction, and build resilient supply chains. As businesses navigate an increasingly complex and dynamic global economy, mastering this lexicon is not just an advantage—it’s a necessity for strategic success. The continuous evolution of these strategies, fueled by technological advancements and changing market demands, ensures that the pursuit of inventory excellence remains a core pillar of modern business management.