Cracking the Code: The Interconnected Puzzle of Business Inventory Strategy

In the intricate world of commerce, few elements are as pivotal yet as perplexing as inventory. It represents a significant asset on a company’s balance sheet, yet simultaneously a potential liability if not managed with precision. The art and science of navigating this duality lie in a well-articulated Business Inventory Strategy. Far from a mere logistical exercise, it’s a complex, multi-faceted puzzle where each piece – or "abbr crossword" clue – must fit perfectly to reveal the bigger picture of profitability, efficiency, and customer satisfaction.

Imagine a crossword puzzle where the answers aren’t just words, but strategic decisions and operational frameworks. Each clue, representing a component of inventory management, is interconnected. A wrong answer in one square can throw off an entire section, leading to stockouts, obsolescence, or excessive carrying costs. Conversely, correctly identifying and implementing each piece of the strategy unlocks a powerful competitive advantage. This article delves into the essential components of business inventory strategy, exploring its importance, key methodologies, common challenges, and the technological advancements that are reshaping this critical business function.

The Foundational Pieces: Why Inventory Strategy Matters

At its core, a robust inventory strategy is about finding the optimal balance between having too much stock and too little. This balancing act directly impacts several critical business areas:

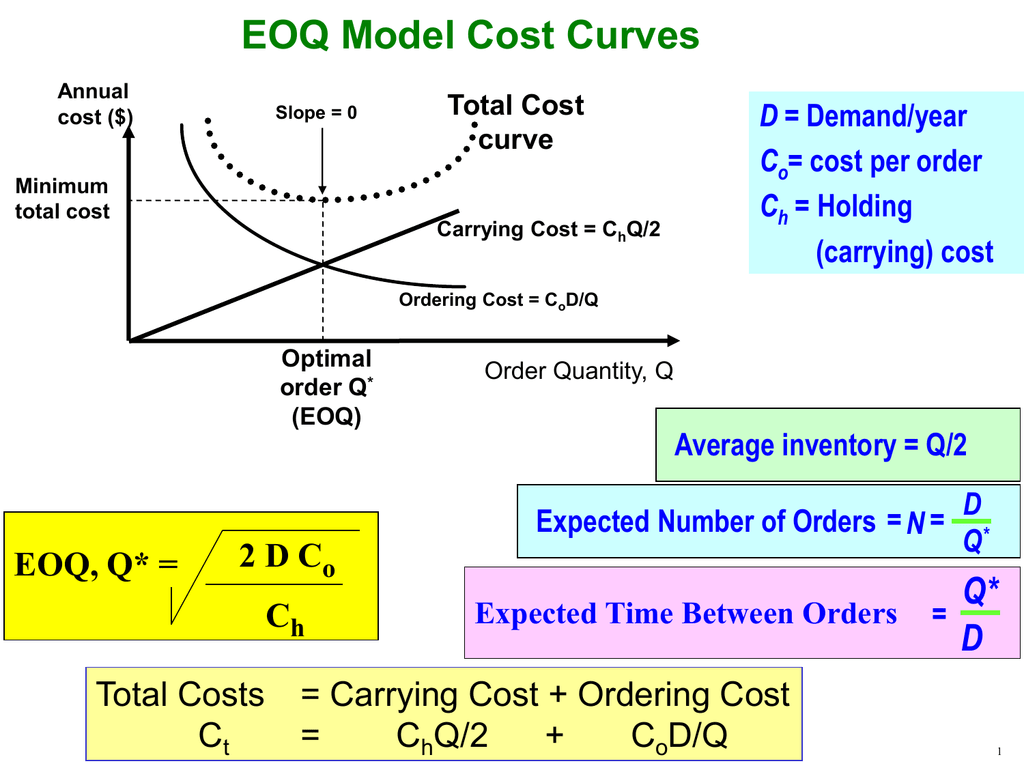

- Cost Reduction: Inventory incurs significant costs, including storage (warehousing, utilities, insurance), handling, obsolescence, and capital tied up. An effective strategy minimizes these Carrying Costs (CC) and Ordering Costs (OC), directly boosting the bottom line.

- Improved Cash Flow: Inventory represents capital that could be used elsewhere. Reducing unnecessary stock frees up cash, enhancing liquidity and financial flexibility.

- Enhanced Customer Satisfaction: The ability to fulfill orders accurately and promptly is paramount. An optimized inventory ensures products are available when customers want them, preventing Stockouts (SO) and improving Fill Rate (FR).

- Operational Efficiency: Streamlined inventory processes reduce waste, improve productivity, and allow for smoother operations across the supply chain.

- Risk Mitigation: While carrying too much inventory has risks, so does carrying too little. A good strategy accounts for demand variability and supply disruptions through measures like Safety Stock (SS), protecting against unforeseen events.

Without a coherent strategy, businesses risk becoming entangled in a web of inefficiencies, lost sales, and eroded profits. It’s the blueprint that guides purchasing, production, and distribution decisions, ensuring that inventory acts as an asset, not a burden.

Key Components & Concepts: The "Crossword Clues"

Solving the inventory puzzle requires understanding and strategically deploying various methodologies and concepts. These are the "clues" that, when answered correctly, lead to a winning strategy:

-

Demand Forecasting (DF): The Starting Point

This is arguably the most crucial piece of the puzzle. Accurate demand forecasting predicts future customer demand, guiding purchasing and production decisions. It can range from simple historical data analysis to sophisticated Machine Learning (ML) algorithms. Ignoring this clue leads to either overstocking (and associated costs) or understocking (and lost sales). -

Inventory Classification: Prioritizing Your Stock

Not all inventory is created equal. ABC Analysis is a popular classification method that categorizes items based on their value and impact:- A-items: High-value, low-volume items requiring tight control and frequent review.

- B-items: Medium-value, medium-volume items with moderate control.

- C-items: Low-value, high-volume items requiring simpler control.

This helps businesses allocate resources where they matter most, preventing excessive focus on trivial items and ensuring critical items are always managed effectively.

-

Ordering Systems & Parameters: When and How Much to Order

- Economic Order Quantity (EOQ): This formula calculates the ideal order size to minimize total inventory costs (carrying costs + ordering costs). It’s a classic clue for optimizing order batching.

- Reorder Point (ROP): The inventory level at which a new order should be placed to replenish stock before it runs out. ROP often incorporates Lead Time (LT) (the time between placing an order and receiving it) and safety stock.

- Safety Stock (SS): An extra quantity of inventory held to prevent stockouts due to unexpected demand fluctuations or supply delays. It acts as a buffer against uncertainty, providing resilience to the supply chain.

-

Inventory Management Models & Strategies: The Grand Design

These are overarching frameworks that dictate how inventory is managed across the supply chain:- Just-in-Time (JIT): A lean manufacturing philosophy that aims to minimize inventory by receiving goods only as they are needed for production or sale. This strategy emphasizes strong supplier relationships, high quality, and minimal waste. It’s a high-risk, high-reward approach that, when implemented successfully, significantly reduces carrying costs.

- Materials Requirements Planning (MRP) & Distribution Requirements Planning (DRP):

- MRP is a production planning and inventory control system used to manage manufacturing processes. It ensures that necessary materials are available for production and finished products are available for delivery.

- DRP extends MRP to the distribution network, planning the movement of finished goods from manufacturing to warehouses and retail outlets. Together, MRP and DRP synchronize the entire supply chain.

- Vendor-Managed Inventory (VMI): In this collaborative strategy, the supplier (vendor) takes responsibility for managing the inventory levels at the customer’s location. The vendor monitors stock and replenishes it as needed, benefiting from better visibility and reducing the customer’s inventory management burden.

- Consignment Inventory: A model where the supplier retains ownership of the inventory until it is sold by the retailer. This reduces the retailer’s financial risk and carrying costs, while the supplier gains shelf space.

- Dropshipping: A retail fulfillment method where the store doesn’t keep the products it sells in stock. Instead, when a store sells a product, it purchases the item from a third party and has it shipped directly to the customer. This completely eliminates the need for inventory management by the retailer, but shifts control to the supplier.

-

Types of Inventory: Understanding Your Assets

Recognizing the different categories of inventory is fundamental:- Raw Materials (RM): Components and ingredients used in manufacturing.

- Work-in-Process (WIP): Partially finished goods undergoing production.

- Finished Goods (FG): Products ready for sale to customers.

- Maintenance, Repair, and Operations (MRO): Supplies used to support production but not part of the final product.

Challenges: The "Tricky Squares"

Even with a well-designed strategy, businesses encounter hurdles that can disrupt the inventory puzzle:

- The Bullwhip Effect (BWE): Small fluctuations in demand at the retail level can amplify into increasingly larger fluctuations as one moves upstream in the supply chain (retailer to wholesaler to manufacturer to supplier). This leads to excessive inventory and unnecessary costs.

- Obsolescence and Spoilage: Products with short shelf lives or those susceptible to rapid technological change can quickly become worthless, incurring write-offs.

- Lead Time Variability (LTV): Unpredictable delays from suppliers can throw off ROP calculations and lead to stockouts, especially for global supply chains.

- Data Inaccuracy: Poor inventory records, whether due to human error or inadequate systems, lead to misinformed decisions and operational inefficiencies.

- Supply Chain Disruptions: Global events, natural disasters, or geopolitical issues can severely impact the flow of goods, necessitating agile and resilient inventory strategies.

Leveraging Technology: The "Digital Solver"

Modern technology has become the ultimate solver for the inventory puzzle, offering tools that enhance visibility, accuracy, and predictive capabilities:

- Enterprise Resource Planning (ERP) Systems: Integrate all core business processes, including inventory management, finance, HR, and sales, providing a holistic view of operations.

- Warehouse Management Systems (WMS): Optimize warehouse operations, from receiving and putaway to picking, packing, and shipping, improving efficiency and accuracy.

- Radio Frequency Identification (RFID): Enables real-time tracking of inventory items, reducing manual counting and improving stock accuracy.

- Artificial Intelligence (AI) and Machine Learning (ML): These advanced analytics can process vast amounts of data to generate highly accurate demand forecasts, optimize pricing, identify potential supply chain risks, and even suggest optimal ordering parameters, far exceeding human capabilities.

- Internet of Things (IoT): Sensors can monitor environmental conditions for sensitive goods, track asset locations, and provide real-time data for better decision-making.

These technologies provide the intelligence needed to tackle the "crossword clues" with unprecedented precision, turning what was once a manual, error-prone task into a data-driven strategic advantage.

Conclusion: The Continuously Evolving Puzzle

Business inventory strategy is not a static document; it’s a living, breathing framework that requires continuous monitoring, evaluation, and adaptation. Like a crossword puzzle, new clues emerge (market shifts, technological advancements), and existing answers might need re-evaluation. The interconnectedness of demand, supply, costs, and customer satisfaction means that every decision in inventory ripples through the entire organization.

By diligently addressing each "clue" – from accurate demand forecasting and strategic classification to leveraging advanced technologies and choosing the right management models – businesses can construct a robust inventory strategy. This mastery not only leads to significant cost savings and operational efficiencies but also fortifies customer loyalty and provides a crucial competitive edge in today’s dynamic global marketplace. The companies that successfully crack this complex code are the ones best positioned for sustained growth and profitability.